All Activity

- Past hour

-

dpz702 started following My glide bait progression

-

Sorry if im in the wrong section but i wanted to share my progress on making glide baits. First bait was maybe july/2023 and the bottom was a week ago. Best thing is they actually glide/swim instead of roll to tye surface. I still need to get better with my carvings as that hasnt improved much, i can't seem to get those nice crisp cuts that i see others make. Maybe im not sanding enough??.

- Today

-

Any chance you could get 1?

- Yesterday

-

dlaery started following Skirt making tool

-

if someone wants to send me dimensions, i'll print one?

-

Good Fishing started following Skirt making tool

-

We stopped carrying this tool around 3 years ago because we rarely, if ever, received them from the manufacturer. Matt Barlow Barlow's

- Last week

-

I will print them. Do you mean, I should make a solid one, check how it is behaing and upon this drill the holes(moel the new one with holes?)?

-

cadman started following Black Brass Beads

-

Welcome to Tackle Underground. Google The Fly Shack and see if those work for you.

-

Make a blank without weight test it and then make the internal one. I test mine then drill the holes, I am assuming yours are machine made or split design.

-

PMaj started following Black Brass Beads

-

Hi everyone first post here. Does anyone know of a vendor that has black brass beads for building spinners? Most vendors have plain brass or nickel plated. Thx

-

bassjiggin1955 started following 3/4 oz Arky Jig

-

Hilts mold Make arkie head molds from 1/8oz to 3/4oz. You have to specify which molds you want. They make there mold with weed guard and without weed guards but on the molds without the guard it is cut down too the jig head but stops just before. That the ones I have i drill it out to insert small pins for 9 and 11 fiber weed guards. Ive hold the molds for going on 40 years now. The molds can be modified to hold a flat eye hook I use all light wire mustad black nickel hooks in my molds Download the catalog scroll down til you found the arkie head jigs They have a phone number leave a message they will return your call.

-

If you find a 3/4 oz Arky jig mold that has a vert. eye hook slot you can use a dremel ro a drill press to modify it to take a flat eye. I do the reverse and it's easy.

-

thanks fpr the answer @Flaswimbaiter! Guess I have to print various, not sure if they survive being openend ans closer several times. thought staring maybe here: or like this:

-

Flaswimbaiter started following Advice on where to put wheights

-

I would temporarily glue a weight on different spots and tank or swim test it.

-

Fishyone777 joined the community

-

All Eyes started following shadulous5.jpg

-

You can use an existing design as a prototype and change the dimensions or alter features of the bait so it is different from the original master. I made a mold years ago that started out as a zipper type worm and I added a big ribbon style tail to it for night fishing . It is around 8-9" long and there is still nothing like it . It's a big bulky worm and works great .

-

I use a mixture of water, alcohol, retarder, and flow improver. You can use just water but you may get a bit of tip dry. 2/3 distilled water 1/3 isopropyl alcohol 99% 1 ml retarder 10 ml flow improver Mixing thoroughly is important so throw some paint mixing balls in. You can get them off of Amazon for $8 for 200. Also before you ever shake a new bottle up, open the cap and clean any dry paint off with a q-tip. You never know how long they have been on the shelf.

-

I use medium for everything except tubes & crappie lures. Since i always texas rig tubes i make them by mixing 50/50 medium & hard to make them a little firmer so as not to tear after a bite or on hookset. My crappie lures i make out of hard for durability since their slid up onto a barbed jighead with the hook fully exposed. The crappie lures don't tear nearly as easy from sliding them up onto the barb & can be used a lot longer.

-

webote started following Advice on where to put wheights

-

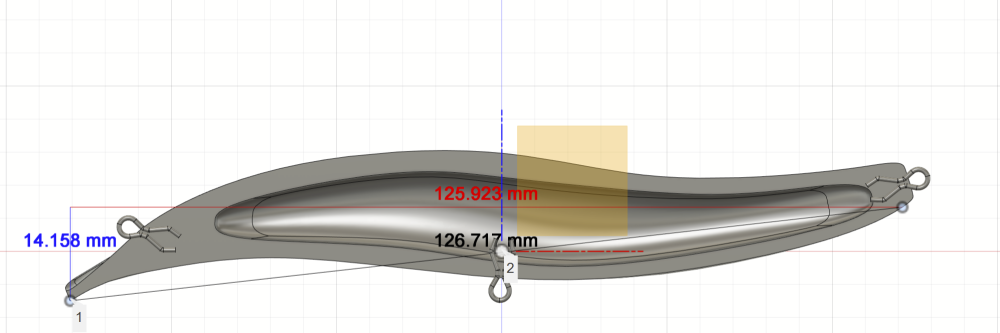

Hi everybody, after a lots of softbaits, I (re-)started my first hardbait. Where would you put the lead in this body? I want it to dive about 0.5-1-5m Thanks everyone and have a wonderful weekend!

-

Searching for a mold for a 3/4 ounce Arky jig, preferably for a flat eye hook. Thanks in advance for all suggestions.

-

I'd have a peak at your local buy/sell like facebook marketplace or Kijiji. Seems like a lot of people have gotten into airbrushing for a brief time and sell it all when they realize they don't want to do it anymore. I've picked up a bunch of Golden/Aztek/Createx paints for a bargain that way.

-

You have a PM

-

Carpkiller joined the community

-

Thank you! Glad to see you back on the forums man! If you get a chance could you please pm me your address. I've got some fur for you that we discussed awhile back.

-

Phthalates have very little to do with it. The issue will be the plasticizers and stabilizers smoking off when the plastic is hot. Those fumes are not what you want to inhale at all. If you pay attention to the exhaust system (unless you're outside you should 10000% have an adequate exhaust system in place) the fumes leave an oily residue. That residue is being left in your lungs when you breathe this stuff in......Regardless if the plastic is "Phthalate Free" (that's a topic for another day) or not.