Leaderboard

-

in all areas

- All areas

- Images

- Image Comments

- Image Reviews

- Albums

- Album Comments

- Album Reviews

- Topics

- Posts

- Stories

- Story Comments

- Story Reviews

- Classified Ads

- Classified Ad Comments

- Classified Ad Reviews

- Records

- Record Comments

- Record Reviews

- Websites

- Website Comments

- Website Reviews

- Status Updates

- Status Replies

-

Custom Date

-

All time

February 2 2011 - April 19 2024

-

Year

April 19 2023 - April 19 2024

-

Month

March 19 2024 - April 19 2024

-

Week

April 12 2024 - April 19 2024

-

Today

April 19 2024

-

Custom Date

12/01/2019 - 12/01/2019

-

All time

Popular Content

Showing content with the highest reputation on 12/01/2019 in all areas

-

I used to use thru-wire in balsa baits but switched to hand twisted hangers and line ties. I fill drilled holes with slow cure epoxy before inserting them. I can’t speak for others but I’ve never had a fish break a lure body or pull out any hardware, which are the only disasters a thru-wire can prevent. If one ever does, I’ll thank that fish for the experience and MAYBE think about thru-wiring again. But I’m pretty sure my line will break or my trebles will fail before that happens. If thru-wiring is done for convenience compared to other methods, that’s different. But I don’t build large batches of baits and for me it’s just more work that I don’t see the utility for.2 points

-

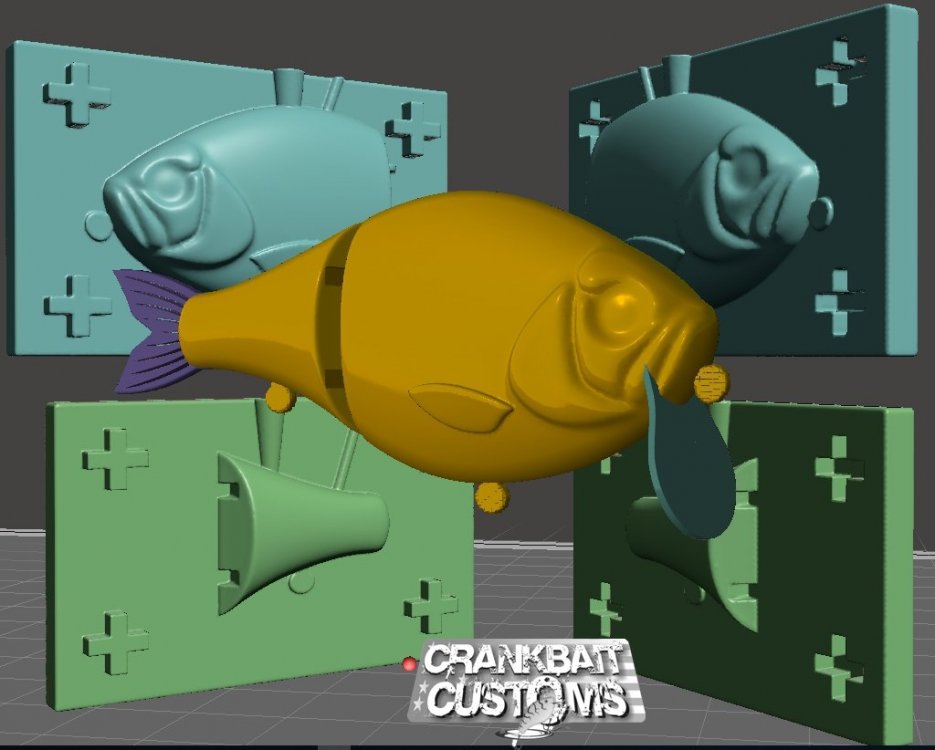

3d printers are great for prototyping, you can have a lure in your hand to test in less than an hour or two. For molding purposes I design the lure and mold as one process and create masters to create molds for resin and foam lures. The mold masters pictured were designed in CAD and printed on an SLA printer. SLA printing is expensive. A decent build volume for a SLA printer will set you back close to 10K just for the base model. Im not sure what CAD program you are working with but I have switched from Fusion 360 to Vetric Aspire and the design and build process is the bomb with Aspire!!2 points

-

To me its your choice I do both, more twist wire epoxy in than screw in or wire through. have no problems. Wayne2 points

-

This has been going on forever, whether in fishing or any other hobby or business. I make jigs, and have been doing it for 20 years. When I started doing powder paint it was in its infancy. I then started doing multi-color jigs out of powder paint with the tap brush method, while a good friend of mine on here Smalljaw was doing multi-color jigs using powder paint with an air brush. In 2005 we were the only two at that time doing this with powder paint. The TU community exploded asking us questions on how it was done. I was selling jigs off the wall with multi-color patterns. Myself and Smalljaw literally posted our process on how it was done on TU. This is a teaching site. To this day I do not regret people learning from what I brought to the table. Some guys were able to accomplish what I taught, others struggled and figured it out and others just could not get the hang of it. Fast forward to today. I don't sell nearly as many multi-colored jigs as I did back then because everyone is doing it. In all honesty, it doesn't bother me. This is a hobby for me, it always has been and it will always be . I cannot make a living making jigs. With that said, I try to help people when I can, and if they steal my ideas so be it. This is my perception on the whole thing. Someone will steal your idea if they can figure it out and if he doesn't then China will figure it out and steal it. It's just the way it goes. Life is too short to worry about inconsequential things. JMO2 points

-

This mold was made from 1980-1983... I have one and looking for another. If anyone here has one they don't need or know where another is, I'm looking for another. Thank You.1 point

-

Really helps. Thanks so much for the detailed explanation and pic.1 point

-

Mason jar with saran wrap under both pieces of the lid.....DO NOT USE A PLASTIC CONTAINER!! I have kept it in a mason jar for over a year with no problems.... My .021 point

-

Thanks Blackjack, I am going in to the lure making process blind. I have read a lot of info in the hard baits forum and that has helped me a lot. I am sure there are many things I don't know. Being able to design lures in cad is easier for me than doing it by hand. Once you make 1/2 of a part, you can then mirror it and you have a perfectly symmetrical other 1/2. Also my 3d printer is coming in 2 weeks, so I will have a lot to learn there along with all of winter to practice and screw things up. As far as software goes I use Solidworks. I use it at my job everyday, and we build a lot of solid models along with surfacing, so the cad side will not be a problem. I've been doing cad for over 20 years, so hopefully all of those years will pay off.1 point

-

I can’t specifically speak to KBS but I’ve used Dick Nite MCU for several years and it is probably even more sensitive to moisture contamination. Pounding the lid back on is the worst case scenario to preserve MCU as it leaves the largest air to finish contact surface and the highest chance of air leakage. It’s also hell getting a can back open after the first use when the MCU has gotten on the lid and cured hard as a rock. Decanting it into narrow necked containers, insuring 100% air seal in a Mason jar, squirting inert nitrogen gas into the container to blanket the MCU, using the “tap the can” method of storage, and dispensing only enough MCU to paint a lure instead of dipping lures in the finish are all strategies that guys use to save their MCU from curing in the storage container. Whether you use any or a combination of these strategies, or none of them, depends on how quickly you will use up the MCU and your pain threshold for wasting money on a rather expensive finish product that easily goes bad due to poor storage methods.1 point

-

Thank you for the insight. I am in experimentation phase now. Mocked up a POP pour mold and poured acetoxy silicone thinned with odorless mineral spirits. so far, the cured silicone seems pretty tough and has the flex i'm looking for. That's a positive. The negatives are that the silicone takes 48 hours to cure and the silicone (DAP from the hardware store) is not very cheap. I am ordering the hard plastisol from LureWorks and will give that a try next. Is there a way to get silicone to cure faster? And will plastisol colorants work in silicone? Thanks, AL1 point

-

If you want to make sure you are not missing spots, hold the lure toward a light and let the light reflect off the surface. When you are at the right angle you won't be able to see color of the lure just the shine of the epoxy. It is very easy to rotate the lure and tell if you have missed any spots by the reflection of the light. I use epoxy and mix it on a flat piece of paper by making two puddles of resin and hardner of equal sizes. I just eyeball the sizes and it doesn't seem to make any difference if off a little in size. I stir the two puddles together with the same brush I am going to apply it with. My thought of your problem is that it might have something to do with the type of paint or maybe a sealer you are using. Epoxy is usually rather forgiving. Good luck. Musky Glenn1 point

-

Call lureworks. they have and sell the hardest plastisol you can buy, You can not inject it, you will have to use other means, But it is very doable. Just plan for it to be an expensive hobby.... This type of plastisol is way more durable then silicone.1 point

-

Attached is a pic of the round ball jig mold RHB-7-A. The hooks that are in there are Owner 5318 #1 . As you can see by the pic, the #1 hook fits the 1/16 oz cavity fine at the top by the hook eye. However, it bridges the boss at the hook bend. With the hook this way at the bottom, the mold will not close tightly and you will get a lot of flash. The solution to this is to remove that material on both sides of the mold. Now my mold is older, maybe your mold doesn't have this. If that is the case then there is no issue there. On the 1/32 oz head, you have a problem at the hook eye, where if you put the hook eye in the cavity where it is supposed to be, your hook shank will butt against the mold. This will give you incomplete pours, so you have to center the hook shank in the cavity. By doing this, you will see that the hook eye has moved. You will need to remove the mold material here on both halves so the hook eye is flush with both sides of the mold in order to close completely. Now at the bottom you have the same issue as the 1/16 hook has and the mat'l needs to be removed here as well. Hope this helps.1 point

-

Thank you cadman. If you do have pics available and not to much trouble I'd very much appreciate posting the pics. I don't want to ruin the mold modifying any wrong area1 point

-

Just a take over from me constantly hanging my jigs in an oven to cure my powder paint. Sometimes I have to bridge the lure (spinnerbait heads ) across my rack, because they are too long to hang vertical and put in the oven. But I have done this for years and it is simple and cheap. Since this is X-mas time, go to the store and buy the x-tra long ornament hangers. I found these to work much better than paperclips or wire. Reason being, they are very flexible. You can bend them to any shape at all, wrap them around things over and over, pull and tighten them around objects and they don't break which means you can use them over and over again. I have tried to twist these back and forth to break them and it just doesn't happen. I think this will solve your rubber band problem. If you wait till after the holidays December 26th, you can buy a box of 50 or 100 hangers for $1 or 50 cent. I usually stock up now and buy ten boxes. May be worth a try.1 point

-

1 point

-

Didn't find any Gamis that would fit w/o mold mods. The Owner 5318 1/0 will not fit in any of the two sizes mentioned above. The Owner 5318 #1 hook will fit the 1/16 oz cavity w/o mods. The #1 hook will not fit the 1/32 oz cavity due to the hook eyelet being too long and the hook bend hits the boss in the mold when it closes. The hook eye can be extended in the mold with a file. The boss on the bottom of the mold can also be filed down flush and removed. If you need clarification, let me know. I will attach some pics here.1 point

-

1 point

-

Owner 5318 hooks will fit no mods. Gami 604 will fit in some cavities. Best way to get a good answer is to let us know what size hook you want to put in which size cavity. This way guys can check to see if the hook will fit1 point

-

I know when i was trying to get a kietech style color look on a swimbait I put a tablespoon of koesher salt to 3 ounces plastc with just a skewer tip of blue to get it. Without the salt it wasn't happening with the colorant i had.1 point

-

1 point

-

If Senko's came with an "ingredients" label attached salt would be the first ingredient .1 point