jigmeister

TU Member-

Posts

333 -

Joined

-

Last visited

-

Days Won

23

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by jigmeister

-

Mad man craw was an anatomically correct bait that looked just like a real crawfish but I think the problem was it didn't move like a real crawfish in the water . From what I can remember from reading about the Berkley testing was that they made a bait to look like a crawfish that the test fish did not respond to in the manner they expected . In an effort to figure out why they started removing the bait's appendages to see what was putting the fish off about the bait . When the claws and all of the legs were removed the fish finally took interest . I remember one theory was that the fish weren't sure what the bait was having never seen anything like it before so curiosity made them bite it ? I think ambiguity could also be a factor . If a lure can be thought of by a bass to be a crawfish , baitfish , or other potential food item they will be more likely to bite it . A tube bait doesn't look exactly like a craw or bait fish but it could be close enough to be interpreted by a bass to be one and a bass typically doesn't want a for sure meal to get away . (Disclaimer : Thats what I think but I get skunked a lot)

-

I like to Texas rig a square of toilet paper on the line ahead of the bait for realism . Big Bass usually slam this rig up as soon as it hits the water with strikes that sound like a toilet flushing .

-

What Kind Of Boat Is The Easiest To Remodel

jigmeister replied to bassbandit25's topic in Boatbuilding

John boat easiest (100% welded hull will have least problems and no leaking rivets to contend with ) -

Anyone Instal The "new" Down/side Scan Depth Finders Yet? Tips?

jigmeister replied to wormsoaker's topic in Boatbuilding

The manufacturer says to run the down scan /side scan with a forward boat speed of up to 5 MPH for best imaging (Idle speed) allowing you to mount it slightly above the bottom edge of the transom . This will protect the transducer from hitting debris in the water when driving at faster speeds . -

are you wanting to make them just for your own use or sell them ?

-

It is most likely they are "Masters" used for making the molds to produce the baits or for a reference of the lure dimensions

- 1 reply

-

- 1

-

-

Mister Twister made the first floating worms I had ever seen in the late 1970's . They were extremely soft and spongy baits with a twister tail that tore apart easily . If you tore one in half the plastic was full of tiny bubbles molded into the plastic . They quit making them and I had heard it was because of something that was toxic (or not "environmentally friendly "they added to the plastic to produce the bubbles. I have often wondered just what that was they were using .

-

Making Your Paddle Tail Not A Paddle Tail?

jigmeister replied to JDNO7's topic in Soft Plastics How To

Before modifying your mold I would suggest taking one of the poured paddle tailed baits and trim the boot tail down to a straight tail so you can try it out as a twitch type lure and make sure it performs to your liking before making the changes to the mold . -

Need help/tips for Airbrushing using Mica Powder

jigmeister replied to Fern's topic in Soft Plastics

From what I have read People who paint plastic baits with airbrushes have to use retarder to eliminate the spider webs that form due to the paint drying too fast . A little but of mica goes a long way I am wondering if you are putting too much mica in the paint cup causing clumping in the tip ? -

Need help/tips for Airbrushing using Mica Powder

jigmeister replied to Fern's topic in Soft Plastics

I tried this with the air brush spray set pretty light and sprayed multiple coats until I was happy with the coverage .The acetone will dry in seconds after being sprayed on but the mica will stay in place . It looks like this is how Basstrix painted their swimbaits using this method then final dipping in clear coat which both seals the mica powder and brings out the color(s) . Give it a try and see what you think -

Need help/tips for Airbrushing using Mica Powder

jigmeister replied to Fern's topic in Soft Plastics

If those are dipped baits you can air brush mica powder mixed with acetone on a finished bait then do a final dip with clear plastic to seal the mica to the bait -

New tutorial on making vertical pour silicone mold

jigmeister replied to jigmeister's topic in Soft Plastics

From main Tackle Underground home page scroll down to "Member submitted tutorials" > "Soft Plastics How To " -

Good for making one piece molds for full round straight tailed worms and stick type baits

-

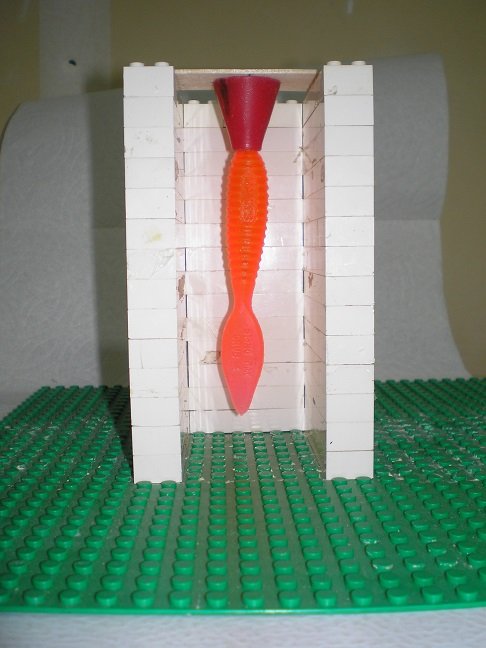

This works great with "no longer available" or hard to find soft plastics like the 4" spade tailed grub below using a mold box (I made mine out of LEGO's sealed on the inside with clear packaging tape) and Platinum cure silicone since the viscosity is very thin and picks up detail without bubbles but is so thin it will leak out of a poorly sealed mold box . Picture below shows a cutaway of vertical mold box with bait hanging from plastic cone glued to this strip of wood serving as sprue to pour plastic . A piece of spinnerbait arm wire is imbedded in cone then pushed into grub body to hold in place . A small tungsten worm weight can be hung on a sewing pin and inserted in tip of tail to insure bait hangs straight (if needed) but this also makes a great vent hole Following manufacturers directions mix and then slowly pour silicone into mold box until desired height is reached If desired you can slowly raise and lower bait in and out of silicone a few times to make sure there are no bubbles sticking on bait Demold from box when silicone is fully cured and gently pull master from mold Pam spray can be worked around sprue hole and top of bait to make removing bait easier demolded mold is pictured below (note how mold box LEGO brick shapes were picked up thru sealing take by silicone ) In picture below is a hard master made from 2 part polyurethane casting resin poured into new mold Polyurethane casting resin can then be sanded or built up /shaped with epoxy to alter original factory bait to make a new design of your own . Make sure to fish with and are happy with your new design before wasting any expensive mold material ! (been there done that) If you ready to start making multi-cavity molds of your new design you can make a new 1 cavity mold with your hard master and pour multiple polyurethane hard copies oriented sprue side down in the sprue box for a multi-cavity mold of your new creation for production without the expense or delay of having an aluminum mold custom made . Pictured above is the original Methiolate grub , Hard master with sprue made in new mold , and new green pumpkin grub poured in new mold shown in back ground . With mold positioned with sprue hole up you can pour plastic into mold with pouring cup . If you end up with a void in cavity or suspect you might you can gently squeeze mold towards the bottom forcing air bubble out then pour more hot plastic into the mold . In conclusion the pro's are this method allows one the ability to rapidly produce and modify prototype soft plastic baits with minimal features with hand pouring in a semi clear mold you create . The cons are the cost of the Platinum cure silicone and the limitation of shapes you can pour and still get finished baits out of the mold

-

I have made some molds out of platinum cure silicone for full round straight tailed baits with the masters oriented vertically in a row suspended off the bottom with fine gauge wire . You can put a big sprue at the top of the mold for ease in hand pouring and removing the bait . after cooling the baits pull straight out due to the give of the mold and bait and no flashing to contend with . The cured Platinum cure silicone is transparent so you can see the plastic when pouring in too. The Platinum cure silicone is expensive but so are machined aluminum molds

-

I started out stripping paint off some bomber crank baits that were clear underneath the paint using acetone with no sanding . I inquired with Bomber to see if I could purchase the baits I wanted unpainted which they said they sold but the price was about twice what one of their painted bait's cost ??? Later I started stripping Rebel Pop-R's with acetone to get a clear popper that lay underneath the smooth models .

-

I have done many over the years using acetone soaked rags . I started out sanding baits but it took forever and discovered using acetone was ultimately faster . With the rag wet just keep rubbing the bait with the hooks and split rings removed . You will see the paint collecting on the rag as you go . When a rag is full of paint discard it and use a new rag again soaked with acetone . when all of the paint is gone a clear bodied bait will look slightly cloudy after all of the acetone evaporates from the surface . I then take a new clean rag soaked with acetone and wipe the bait in one direction (head to tail) 1 time each on the top ,sides ,and bottom of the bait and set aside to dry to remove any cloudiness or thin paint residue on the surface . (sometimes you may have to do this final step a couple of times but usually not ) Use the real acetone from the hardware store not the scented stuff for removing nail polish .

-

Has anybody tried to make a soft plastic jointed swimbait?

jigmeister replied to RiverSmallieGuy's topic in Soft Plastics

Do a search on "Castaic Catch 22" swimbaits . They were soft and had multiple joints with a flexible mesh material molded into the bait . Sounds like what you're asking about . -

Recipe for "Keeper Custom worms" 082 color

jigmeister replied to jigmeister's topic in Soft Plastics

Wow thanks for the tip , When Keeper quit making baits I had heard that the original owners had given the business to their son (who had trouble keeping up with orders and eliminated a lot of colors ). Next the sister in law who poured baits for Keeper Custom worms started Wrights Bait company and brought back a lot of the lost colors . I found some Wrights and bought the equivalent of the original 082 color years ago and this matches what Wrights has on Ebay for sale so it must be the same "Wrights " from all appearances ... -

Keeper custom worms based in Reedley CA. was taken over by "Wrights bait co " who continued some colors but I don't know if Wright's is still in business but can't seem to find them . I bought up a bunch of the 4" 082 st worms before the supply dried up and now running low . Any out here master the color of this old school split shot worm . This 2 color pour is a light transparent brown and watermelon / chartreuse mix . I'll have to get a picture attached for clarification .

-

I would suggest trying a different type of paint for the eyes . Only jig heads I paint eyes on are swim jigs . I have been using enamel in a 1/2 pt can from wally world and have had no issues . I only use yellow paint with a black dot in the center though .

-

If you have a dial caliper you can measure the hook wire diameter you want to modify the mold to fit and get a dremel ball cutter that matches the hook diameter as close as possible . Don't forget the hook eye diameter will sometimes also be bigger so I also measure and using a drill bit matching the hook eye size and drill a shallow hole in each mold half . Closing the mold on the desired hook size and striking with a hammer ( or pressing the mold between the jaws of a vice also works) to make an imprint of the hook in both mold halves . I have used the dremel ball cutter bits in battery hand drills and a drill press over the years . I start on one half removing aluminum and occasionally laying the hook in the slot I am cutting . Eye balling the hook I try to only cut deep enough so 1/2 of the hook wire diameter is resting in the slot then I start cutting the other half of the mold repeating the process . When cutting the second half I also try closing the mold up on the hook until it just closes . If you remove too much aluminum from the slot you cut the hook can roll off to one side slightly which is not desirable so that's why it's best to go slow . If you remove too much metal you can use JB Weld to fill in any mistakes .

-

Great Idea ! Thanks for sharing

-

looking to buy a single cavity fake stone type mold for 4.95 Flirt style worm . Someone in Ukraine was selling them on Ebay and is out of this mold . Anyone have one they no longer need