-

Posts

4,234 -

Joined

-

Last visited

-

Days Won

104

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by cadman

-

I have not seen any powder paints that have a shiny gold color to them. Your best option for that is get them plated. However that is a costly process for small volumes.

-

You can also use Durham's wood putty. But make sure the mold is completely dry before you pour lead into it.

-

You are correct, I have that mold as well with weedguard hole. There is an 1/8z one as well but no weedguard hole.

-

I do not believe they go down to 1/8-1/4 oz. Maybe they do I will have to look that up. I can tell you this, my nephew uses the grass jig and he does really well with that jig and a trailer.

-

Thanks for the info.

-

Jig Man, When you bake your jigs with the pins in, do you have any problem with them sticking to the paint and or chipping when you remove them after the paint has cooled? I have always took mine out as soon as I dipped the jig in the powder paint before baking.

-

First, I'm going to tell you that Smalljaw (my best on line internet friend) go way back. He and I started on TU about the same time (2006). I will also say from knowing him for so long, he is a wealth of knowledge. I have learned a lot from him over the years, and there are still things I learn to this day when I speak with him. Just a wealth of knowledge. Not to take anything away from anyone else that contributes on this forum. Tying with thread is just as good as tying with wire. The reason I asked if you hand tied, because I knew you were concerned about the skirt sliding down. I know a lot of people that just use rubber collars, and after awhile they dry rot from the sun and the skirt falls apart. That will never happen with thread or wire. I also know a lot of guys use their old braid to tie on skirts and that works well just like you do. As far as gluing the trailer onto my jigs, I do not use anything. I mainly use paca chunks or other crawfish type trailers. I do not have a really big problem with my chunks sliding down the hook shank since I have such a small jig profile with usually a 1/0 hook. On the bigger jigs, when I wire tie my skirts, I leave two longer tag ends, and feed them back into the chunk to hold it in place better and it seems to work really well. This process can be done on smaller jigs as well if you want to hold your plastics on better. I have a pic of this somewhere, when I find it I will send it to you.

-

You can try it, but of all the people that I have talked to, the easiest was to cut it on a band saw with a course teeth. People have tried propane torch, ax, scroll saw, table saw and hand saw. All of these processes were way to slow. Unfortunately the easiest is to take it to a big melting place and have them pour manageable ingots. But I'm sure that that is costly. The problem with anything that cuts fast and generates heat will gum up the blade and get the blade stuck in the lead. I have heard of chainsaw as well but that was apparently dangerous. With that said my only answer is slow and steady. That is why I don't like to get big chunks of FREE lead. How the heck are you going to cut it and if you do how much time are you going to spend cutting and maneuvering it. Cheaper to buy small pieces. Good luck and let us know how you make out.

-

Wow for someone who is only 18 years old, you sound like a seasoned veteran. Where did you learn all of these tips you use in making your jigs? I am very impressed. Can I make a suggestion. On your rubber gloves, try to use more fitting gloves that are not so loose. Reason being is if you are using a drill in such close proximity to your fingers, the drill bit might grab the rubber glove and twist it with your finger in it possibly causing damage to your finger. Just a suggestion. Also, if your weedguard hole pocket is deep enough, you can put a teflon pin into the hole, dip it in powder paint, remove it and then bake your jig. Finally, I can't tell, but do you wire tie? If not, try it it will keep your skirts in place and they will never fall apart. On another note, I started pouring jigs about 20 years ago, because like many guys I could not get what I wanted. I was and still am a die hard Itsy Bitsy Bug jig fan from Strike King. I used there jigs for about 4 weeks and found that there weedguard and hooks were very subpar. So I happened to be talking to someone at the time (mind you this is pre-internet days)and he showed me a jig (Snootie Jig) mold which was made by Do-It molds. He built me a couple I tried them, really loved the small profile and I bought a mold, pot and hooks and that is how it all started. To this day, the Snootie jig in 1/8, 3/16 or 1/4 oz are always on one of my rods. I am a finesse jig fisherman. I rarely will throw anything heavier than a 1/4 oz. jig. Mind you I rarely fish deeper than 10 F.O.W.

-

I assume the green color on your jigs is wrapped thread and then epoxy over it to keep it in place and this keeps the skirt from sliding down the jig shank? I don't know if this next idea would work on this jig, but some guys put a groove in the lead shank with a pair of cutters. The groove then acts like a place to tie your skirt onto. This may save you time in tying thread on the hook shank. Also, I noticed you put a weedguard into that jig. Did you drill a hole in the jig head? If so, how difficult was it and what did you use to get the hole in that head. I know it can be a pain sometimes to drill thru lead, and many times almost impossible, as the drill bit grabs the lead and usually rips open the hole. Nice, thinking outside the box.

-

I just checked on the 8/0 Mustad 32824 hooks and they will fit in the 2, 3, 4, 5, 6, 8 oz cavities of the Ultra Minnow mold.

-

Welcome to Tackle Underground. Nice looking jig.

-

Battlefield wire was one company, but it was bought out by Hagens. There is also Mustang Wire http://www.mustangwire.com/ Finally O'Hare spring in IL https://www.oharespring.com/wire-forms

-

There you go, now go and tie some jigs.

-

Pete, what are you trying do accomplish, keeping the two rings free from paint? If so, I don't worry about it. I just take a pair of forceps gripping one ear, dip in powder paint and bake. If you want to take the paint off of the wire ears, take a dremel and a wire brush, and clean them before you bake. Comes off much easier. Once clean bake your ear ball lure.

-

I'll take a look to see if I have a 8/0 hook in the 32824 hook. If I do I will verify fit. This is a very good and strong hook. You won't be disappointed.

-

I pour a lot of these for a customers. I am using Mustad 32824 hooks. 1 oz................ 5/0 1-1/2 oz......... 5/0 2 oz............... 6/0 3 oz............... 6/0 4 oz................6/0 I don't think a 7/0 or an 8/0 will fit these sizes without mods. The 7/0 and 8/0 might fit in the 5, 6 or 8 oz

-

I didn't think the 570 h's were that thick (.046) but apparently they are. Maybe I was thinking of the old Mustad bronze hook that was around (.039-.040)

-

The 630 is an O'Shaughnessy Jig Hook, there is(was) an exact 570 hook profile only in a heavier wire.

-

Jeff I inquired about these hooks several years ago, and if I recall correctly EC didn't make them anymore. Now someone somewhere probably has some in stock. The question is who.

-

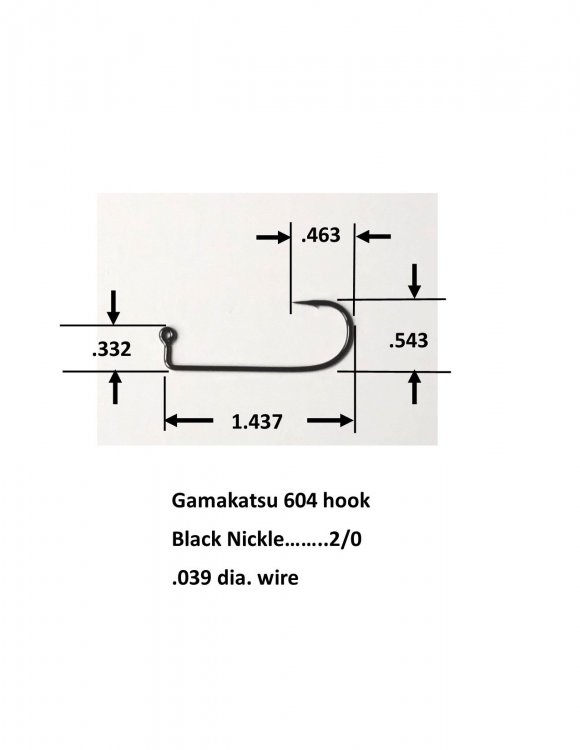

Jig Man, The closest I found to what you are looking for is the Gami 604. See attached pic. These numbers are almost there with-in a 1/16 of an inch in length and close to the other dimensions. If you need more dimensions, let me know.

-

Jig Man do you have a pic with dimensions and maybe a wire diameter size? A Gami 604 hook is heavier than a 570. You have a PM from me.

-

I've done the same thing Smalljaw has done with a 91768 Mustad hook. My sizes are as follows 1/8 oz = 1/0 1/4 oz = 2/0 3/8 oz = 3/0 and 4/0 There are times depending on what batch of hooks that I get, that I have to tweek the hook shank, because it pushes up against the cavity at the top by the hook eye and won't let the lead fill. By bending the hook shank slightly this will solve that problem. This is not one of my best pouring molds, but if you watch how the hooks sit in the cavity when you pour, have enough room around the hook to let the lead fill, and have really hot lead it will fill fine. If you plan on using a 32886 hook in this mold for the strength of the hook, this hook even in the 3/0 size will not fit in any of my modified cavities. What is happening, is the bigger the hook, the closer the bend from the hook eye to the hook shank is up against the area where the sprue is. This will cause the bottom of the hook to not fill with lead, because the hook is in the sprue space. Also the hook eye is too thick to fit in the existing mold eye. There are a lot of things going on here that prohibit using thicker hooks. This mold was really made for Aberdeen style hooks. I think if you can find a hook with a 15º bend on the shank instead of a 30º or 28º in a heavier hook that might be a start. Also you can look into possibly using a rounder shank hook like (picture below). These hooks are found in Lure Parts On Line catalog on page 36. They are flat eye, but they might work better. Then lay the hook on the mold orient it where you think it would pour the best and carve away. If you find a solution to this with a heavier hook and it pours well for you, please reply back with pics of the carved mold and finished raw jig. I am sure many would like to see what you have resolved, if you don't mind sharing. Good luck.

-

Welcome to Tackle Underground. I've never seen them that heavy. You will probably have to nave it custom made, or make yourself a mold out of Durham's wood putty if you aren't making a lot of them.