-

Posts

2,392 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by hazmail

-

Any DIY Paint Booth Filter Recommendations?

hazmail replied to danthefisherman's topic in Hard Baits

Yeah, I remember the U.S was famous for a few Silo explosions (wheat dust etc). They used to show them to us at work quite a lot. Wouldn't like to be there, pretty spectacular though. -

Any DIY Paint Booth Filter Recommendations?

hazmail replied to danthefisherman's topic in Hard Baits

Hi Marc- You would think it would,,, as its that collapsible AC ducting 4". As with PVC tube, some say yes, others say it's all B/S- I suppose to be on the safe side it wouldn't take much to do, never been zapped yet, but if it exploded it would be a drama. You probably remember I built this one years back and have added 2 more tubes since, which works much better-- Its a "downdraught" set up, air is drawn down then up through the 4 tubes to the "Fan Box" and then expelled outside, through the shed wall. -

Any DIY Paint Booth Filter Recommendations?

hazmail replied to danthefisherman's topic in Hard Baits

Hi Dan Not sure if paper filters would be the best option for paint. I know there are a lot of people using them but as you say the motor H.P requirements need to be big . The problem with paper /fiber glass is paint tends to dry/ or "set" very quickly when blasted with air (especially thinners based paints), so it will quickly start blocking the filter which restricts the air flow which allows more paint to set in the filter, so around and around it goes and probably starts drawing air around the filter or from the back. Lots of guys use "flash proof" Gas Heater fans from old home gas heaters. The overspray is transferred (suction) via a spray booth (box) into corrugated plastic or Al (heater ducting) ducting along which it travels through the fan (squirrel cage heater fan) and out to the atmosphere. If you use enough flexible ducting (4" or Bigger) the paint solids tend to set in the ducting, not the fan blades, the solvents or water will be expelled through the fan- which MUST BE FLASHPROOF. Connect the ducting via PVC pipe fittings. Bash the ducting occasionally and the paint solids will fall off as paint dust. Had one for years and still works as new, still passes the required air volume tests too. Pete -

Nice "Flaswimbaiter " & Marc, I might try those hooks, it looks "weedless" too, especially on a surface lure. Pete.

-

There should be a tutorial on heating/bending polycarbonate bibs etc on here somewhere (if you can bear reading it). It was posted about, must be 10 years back. pete Here it is: Just click on the bold "Lip Former PDF"

-

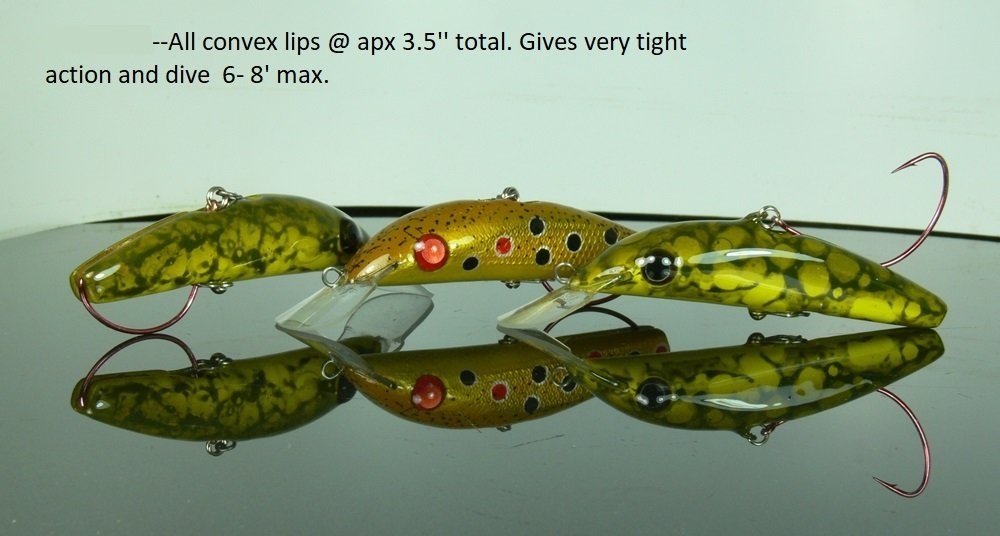

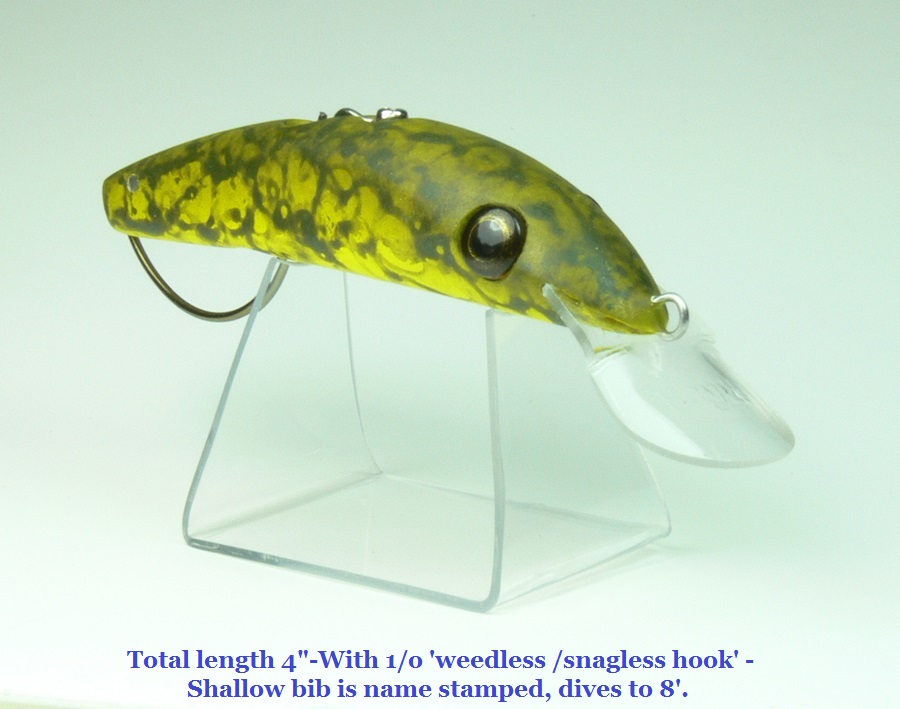

Thanks Barry. No these were made and posted here (I think) 4-5 years ago, I don't think there was any contest back then. Here are 2 more .These are 2 of my favouriotes. Sorry about the Font and layout ,, something wrong --Pete

-

These lures all have magnets (1/8" dia disc "super magnets") which are light and hold on quite well. I made them to be "snagless" for fishing in shallow weedy water- the magnet is in the slot about 3/8" below the hook eye in all these versions.

-

I occasionally use CA and like most here I use my finger. BUT I am a bit hesitant to use it all the time as I'm sure I heard years back it has "Iso Cyanates" in it . This was a problem with the 2 Pack paint systems (Very toxic)---might be worth checking it out. Hope I'm not crushing any toes here, it's nowhere near as bad as I thought. Pete From Wikipedia : https://en.wikipedia.org/wiki/Cyanoacrylate Toxicity[edit] The fumes from cyanoacrylate are a vaporized form of the cyanoacrylate monomer that irritate the sensitive mucous membranes of the respiratory tract (nose, throat, and lungs) and the eyes. They are immediately polymerized by the moisture in the membranes and become inert. These risks can be minimized by using cyanoacrylate in well-ventilated areas. About 5% of the population can become sensitized to cyanoacrylate fumes after repeated exposure, resulting in flu-like symptoms.[33] Cyanoacrylate may also be a skin irritant, causing an allergic skin reaction. The American Conference of Governmental Industrial Hygienists (ACGIH) assign a threshold limit value exposure limit of 200 parts per billion. On rare occasions, inhalation may trigger asthma. There is no singular measurement of toxicity for all cyanoacrylate adhesives because of the large number of adhesives that contain various cyanoacrylate formulations. The United Kingdom's Health and Safety Executive and the United States National Toxicology Program have concluded that the use of ethyl cyanoacrylate is safe and that additional study is unnecessary.[34] The compound 2-octyl cyanoacrylate degrades much more slowly due to its longer organic backbone (series of covalently bonded carbon molecules) and the adhesive does not reach the threshold of tissue toxicity. Due to the toxicity issues of ethyl cyanoacrylate, the use of 2-octyl cyanoacrylate for sutures is preferred.[35]

-

Whats The Hardest Most Durable Clear Coat On The Market?

hazmail replied to CatchemCaro's topic in Hard Baits

Single Pak Epoxy (thin) ---Chris. Pete -

Whats The Hardest Most Durable Clear Coat On The Market?

hazmail replied to CatchemCaro's topic in Hard Baits

I have been using UV Clear Epoxy for a while now and appears to be pretty good. I have had a 2 inch "puck" on a piece of tape stuck to the side of the shed (in full sun and frost) and have been checking for colour change and brittleness for about 2 years, hasn't changed at all, still quite clear and still bends without cracking. What I like is you can paint it on, warm it up and rotate it (if you want), cure it for 15 sec with a UV light/torch and its all over--give it a bit of sunlight for the final cure---no more gunked up brushes, OR doing 6 at a time, and waiting 12 hours before you can touch it AND it makes my colours POP---(make sure you use an exhaust fan if indoors). I've been making lures (trying to) since 1979 and this stuff has given me a new lease on life, there's an extra day in every week-----It's a bit like getting a dishwasher or washing machine Just ask your wife. Pete -

Andy--These things just grow in your head, I seem to be forever adding something, last week it was a new wiper motor (1995 Honda Civic ) which replaced a 32V geared laminator motor- Yesterday it was add a small linear motor, today it's wire in a micro switch to to change the way the chuck "unlocks", it never ends. Pete

-

Dave, I just realized this topic is 18 months old Thien Baffle for Dust Collector : 21 Steps (with Pictures) - Instructables Pete

-

The "Thien Seperator" is pretty good and easy to build, plenty of plans around. (Googe) I have one attached to my copy lathe but it still misses a tiny amount of the very finest dust, so on exit from the separator I put the air through a water mist, this cleans it up nice. If you build one (Thien Seperator) pay particular attention to the air "swirl" @ entry and exit, makes a big difference. Pete

-

Wow love your work Jason, i have been on leave from TU for a couple of years and missed this post. I went through pretty much all you are doing now in 2015 -2019 , and although different to look at the technicalities/ problems look exactly the same, I think I'm up to Version 5 now - ,,,, I'm thinking (hoping) you are now playing with a near complete machine by now, although I never seem to finish, there's always an improvement that has to be incorporated. Last year ?? Because I don't use Balsa for blanks (usually mahogany) I changed the drive from chain to toothed belt (Gilmer belt) drive to eliminate backlash and noise & much smoother - these belts and toothed wheels are readily available on the "Bay" and at a reasonable price. Pete

-

andy- Recently curiosity and idle hands has got the better of me, so in earnest I have started making lures again (also my tackle box is low) and its time to get the copy machine going (needs a new transformer). So I just Googled "copy lathe" and up came TU and this thread ... I also looked up YouTube to see what was the latest on "copy lathes" and up came this interesting, eccentric character (English of course) . Here he is explaining in simple terms how a copy lathe works (2 x dimensional) while he is building one. Beside myself, I thought you and others may be interested : Enjoy Pete

-

Hiro, glad to see you back, it's been a long time. Dave, how is the virus going up there, hope all is well. Pete

-

Try U.V epoxy, this would cut your time to 5 minutes instead of 24 hours. There are all sorts of U.V (Epoxy) available these days, especially over there, go for quality not price. Pete

-

Try ''U-Pol - Grip # 4'', it could be handy here. I have used it quite a bit with gold / silver and copper leaf to promote adherence, with good results on these surfaces, although they are sheet metal, when polished they are just as slippery as foil. You may have to modify the compound once out of the spray can, so you can lightly spray the foil. Test it first - - - - - - - - - - - - - it's supposed to work on a wide variety of surfaces (made for aid in spray painting cars, dries clear). Pete

-

Heaps of "X Rays '' here, all makes and very informative. http://www.lurelovers.com/forum/rare-aussie-lures-expos-what-lies-beneath_topic954_page1.html?KW=lure+xray Pete

-

For what it's worth I too have thought some on this, BUT having no knowledge of "Hard" maths (anything above algebra) I would have acquired a set of fish scales (with memory) hung the ball off the scale with something that doesn't stretch much,,Drop the ball and the weight (shock) will be recorded on the scales for you to read ---Just make sure you catch the ball before it drops again as it will probably cancel the last traumatic event. No matter what size ball all results should be relative, as long as the hanger wire remains the same length /thickness and the drop height remains the same. Remember, double the ball diameter is 4 X the mass. I THINK!! Was it ''Newton'' who got hit on the head with an apple ?? As I said I never did get to try this. Pete

-

Yeah Dave, that's 5 times normal speed , but an admirable goal none the less . I went down this road too, but I was probably aiming for something in the 80-100 RPM range , I was trying to dampen the 'bounce' with mini oil over air shock absorbers - didn't work, too complicated!! Then magnets sounded quite plausible, but never went there ??--I settled on 60 rpm and 2 cutting blades, a leader and finisher, still a work in progress---I also found lead angles make a hell of difference. Using reasonably hard Mahogany & not Balsa tests speed and feed. Pete

-

Thanks Mark I hope so!! Sorry, I got a bit carried away above, (there is a lot of years there)- I was trying to demonstrate how with one curved lip, and the same or a similar blank you can have so many options in depth and action--a lot of people don't seem to get it though.

-

HUMMMMM!!

-

Dave think CNC------------ ''Ball Screws'', no end slop---& '' linear bearings'' no side play. They are quit inexpensive, maybe not to ''CNC standard'' but perfect for our tolerances . Lots of other stuff too, wire tracks, mushroom bearings , screw end bearings etc. https://www.ebay.com.au/itm/Brand-New-Ball-Screw-1Pcs-SFU1204-250mm-1500mm-End-Machine-With-1Set-BK10-BF10/303039958559?hash=item468e96ce1f:m:mNnHLtd5W9N2Eqt-JCFnwPg&frcectupt=true Pete