bassmaster7938

TU Member-

Posts

28 -

Joined

-

Last visited

About bassmaster7938

- Birthday 08/13/1984

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

bassmaster7938's Achievements

Newbie (1/14)

20

Reputation

-

I am looking for the material to use in making swimbait tails like the river 2 sea s wavers, roman made baits, gancraft swimbaits, triple trouts etc. I want something that has some rigidity but yet flex when a fish hits it. I already have my silicone molds done. I purchased alumilite flex 40 and I do not like that stuff at all. It is not strong enough to even push into a slot on a swimbait tail section. It also cures full of bubbles that are not there when mixing. I am thinking something like smooth-on 60d, 61d, or 65d product? I would like to stay away from rubbers as im not having a favorable experience with alumilite flex series. Any help on what to use is appreciated!

-

-

-

I have been working on making jointed swimbaits and glide baits, as you can see here. I have a few molds done and ready to pour master molds to cut joints, install hardware, and ballast etc. I have featherlite kit right now, I am trying to achieve a nice slow sink on everything to start and then floating possibly. I looked at every single thing I could find on the internet about these two, I do know that alumilite sinks and microbaloons used to allow it to float or achieve buoyancy. Is it easier to get a swimabait to float with alumilite product or just stick with featherlite and add weight to get a slow sink. All of my baits right now are 6" and less. Some will have 1 joints some will have 2 or 3. The reason I did not cut up my original carvings was because I want to be able to make multiple offerings of the same model, kinda like how roman made has the glide bait and also a jointed version of the mother. It would be nice to not have to drill holes and just be able to cast for the most part. I also thought about using different resins in pouring to cast a heavier belly section and a lighter top. Whats your thoughts on the best direction to go?

-

Best drill bit for boring plug belly weight?

bassmaster7938 replied to stumpjumper16's topic in Hard Baits

I use forstner bits too -

I think this is the correct pattern http://www.ebay.com/itm/Abalone-vinyl-graphic-decal-sheet-craft-cutter-/272265139131?var=&hash=item3f644453bb:m:m94MEflV0cJ-t3MaH2CvrBw&vxp=mtr

-

THanks guys im going to look around to see if I find any now I know what it is referred to as.

-

-

It will be 6.25" with hardware.

-

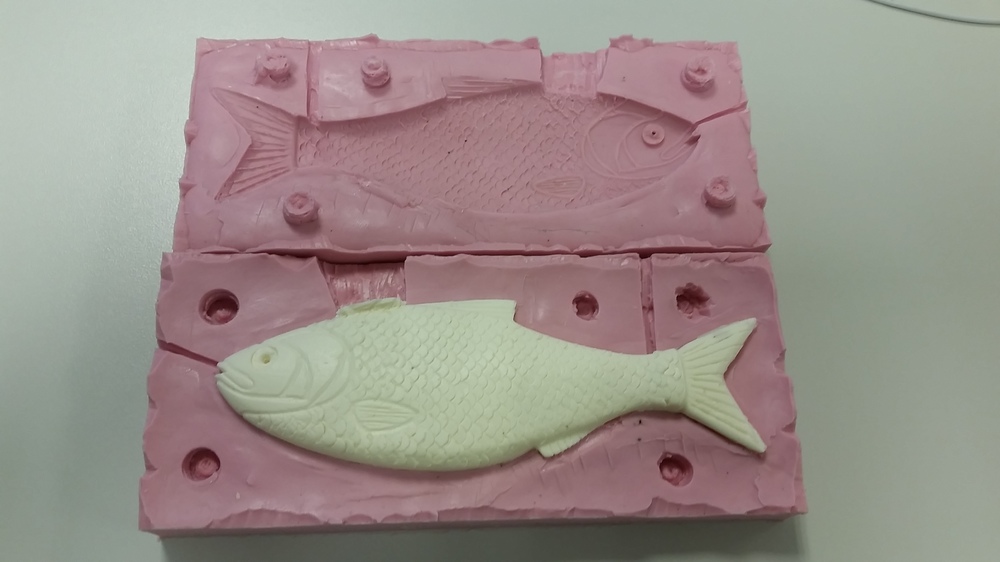

We shall see hopefully it works out this way. I know as far as getting the bait symmetrical, its spot on. I actually used a roman made outline and proportions to make mine. If it doesn't pane out I got plenty of silicone to make a new mold. Mold came out great. I am going to pour a resin prototype soon. Based off a recommendation from a good lure maker I went with Featherlite.

-

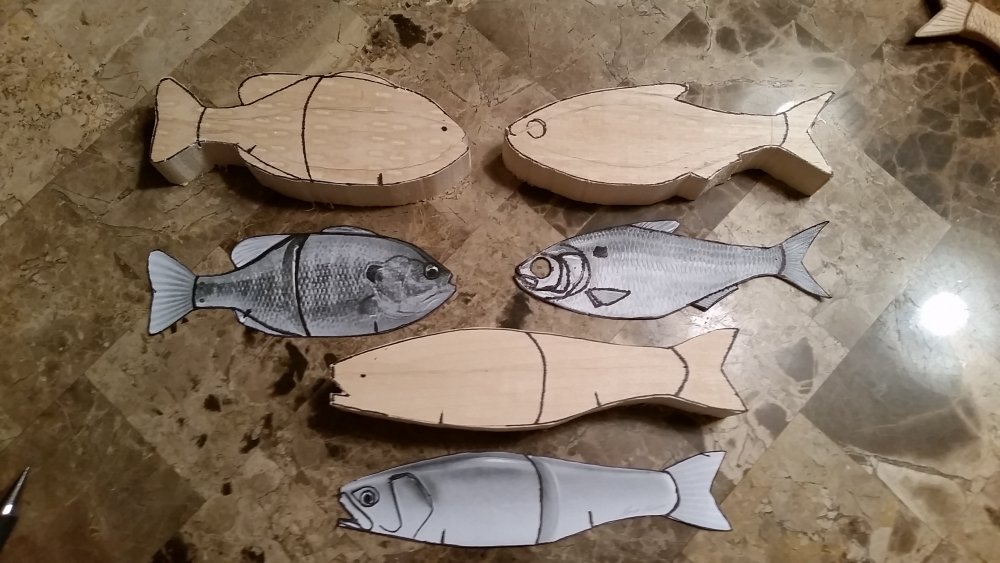

With cabin fever in fool swing, I got tired of airbrushing someone else's knock offs so I decided to come up with my own swimbait designs make them for myself so that if I lose one in a brush pile all I got to do is pour a new one. I plan to sell some here and there to cover all the costs. I really like the mike bucca bull shad but I felt for $50 plus I could make one much better which motivated me to make them. I have always made tackle so this was my new challenge. Here are my carvings I have been working on for the last 20 hours or so. I will have 2 shad types, 1 bluegill, and 1 glide bait modeled after a roman made mother with my own touches and measuring at a tasty 6.5" finished. I am making a master silicone molds for each one to pour resin swimbaits. Once the master molds are made and I make a resin copy, I will cut them into joints, install hardware test tune once they are ready for production. I will then make production molds of the actual baits. I want to keep the wood prototypes original. I want the master molds to be solid one piece so that if I want to make different versions of each one like adding more or less joints or mods of the same lure I don't have to carve another one. Its a big investment in silicone mold material but I think its the way to go. Here is my progress so far. My 6.5" Roman made mother prototype mold is poured and curing. I have along way to go, but I think headed in the right direction. I will keep this updated along my journey of finished products. I now understand why people charge so much for custom baits, so much time into design, then you got to design, make equipment and jigs to get the job done, carving tools, silicone and plastic resins, then mold making, tweaking, testing, tuning, pouring production molds, pouring resin baits, hardware, airbrushing and top coating. Hope you enjoy. I already have a healthy investment into everything from carving tools, scroll saw, dremel and supplies, drill press, supplies, hardware etc. and I am not even done with the molds. THanks to everyone on here for the wealth of information. I will keep this updated along my journey of finished products.

-

Chemmaster Polyseal Ez Concrete Sealer For Topcoats?!?!?

bassmaster7938 posted a topic in Hard Baits

Long story short, in my area I cannot find anyone that carries GST or EAgle brand sealer, and I cannot find anyone that will ship it to me. I have been using ChemMAster PolySeal concrete sealer on my driveway over the last few years and I really like it for that purpose. I have about a gallon left over, I thought about trying it. I am a newbie to the airbrushing world, but I do want to dip my top coat. What are your opinions on this stuff? http://www.chemmasters.net/PolySealEZ.php -

thanks!!!!

-

I went to use Devcon 2T 30 min epoxy this weekend and it was a little tough to work with. I have a hard time spreading it out and get a nice average coat on the jig head. Is there anyway to think it out a bit to make it easier to brush? Thanks!