-

Posts

394 -

Joined

-

Last visited

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by atrophius

-

Rebel Crawfish Perforation And The Elusive Square Bill

atrophius replied to ArdentAngler's topic in Hard Baits

I havent posted in a while, but I am getting back into building. i used to order a lot from jans netcraft. they have square bills that you can run a few trials with maybe. Thats if you are going to try and make some. http://www.jannsnetcraft.com/crankbait-bills-lure-lips/ They have the circuit board ones(which are really thin) and clear plastic(which are standard thickness). -

http://www.tackleunderground.com/community/topic/11512-slip-molds-for-hard-baits/ Check out this slip mold tut. I am sure you could suspend a weight the way he is doing it to hold the master copy.

-

Hey there, I posted on your other comment as well. I dont have anything in the way that is available for you to sell, i never sold any of mine really. Just a suggestion or two if you dont get any bites on the supplies. Painting the lures can be done really easily. Some craft paint for $1 each at michaels and some brushes/sponges will probably do the trick. A little help for them to paint the eye maybe. One idea you can do if you have the start up for your first round of lures. Let them make them, paint them, clear coat them, and get some cheap key rings from a craft store etc. Maybe have a sale at your church for "lure keychains" that people can buy. I am sure any self respecting church goer would be very happy to pick up a keychain like that. They dont even have to be percectly painted lures, they can be themed liked flags, nemo, etc etc. i wish i could help you out, however, I just dont have the materials at the moment.

-

I think that is a great thing you are doing. I am not sure how old they are, but holding their attention to the finished product might be an issue. I take a 9yo boy out and do things with him, he gets bored of tedious thing fairly quickly. I would suggest getting some basswood blocks from a hobby store, some rough wood files, sandpaper, and some eye screws. Draw up some templates they can trace on to the block and let them goto to work. They will be "hooked" a little easier finishing a simple bait they can use sooner. Of course you could research some things on here that you should know (that they necessarily dont have to) about. Such as ballast, lip angles etc. Just my 2 cents.

-

I searched for #214 wire and did not come up with much. I work in surgery and we use pins and wires to fix certain fractures. We generally use anything from 1.25mm to 3.2 mm. The only thing I can come up with on that number is that it is missing a " . " . If it was 2.14 wire @13/16" , that would convert to 0.08425 @ 13/16. So i dont believe based on the only thing i could come up with, that it is the same. less then a hairs difference though.

-

Just my 2 cents, I found a rotisserie on craigslist pretty easily. I just plug it in and fashioned some dowels to stick on the spikes that hold the meat on.

-

I know this is older, but oak also has a very open grain. It will take a good amount of filling to get rid of grain. Poplar has worked good for me and can be shaped well. If you really want to use a hardwood, cedar maybe?

-

-

-

Ok, so I thought I would post a picture of what I came up since someone asked. I pretty much just took a dremel mini router attachment and epoxied it into a piece of wood. I am not done with it yet because there is a whole other section i want to try and make. This thing will eventually be a mini lathe/router hopefully hehe. I am not sure I will go that far yet though, I have school coming up. Pretty much though, the attachment put in the would is square with the surface of the wood and it holds the dremel just fine. I am not a wood worker really, so the construction is not all nice looking, but it is solid.

-

Checkthe other forum post on here, "Excellent mold tutorial". There is some good info in there. Also, I had been thinking about the same thing you have about molding around the lip in the mold. However, I came to thinking about different lips and what if I wanted to make a shallow version or a deep diving version. So I think you could probably make a slot to mold around it, but it may be more counter productive to do so as your limit yourself to just that lip. Plus I like to eyeball the lip alignment.

-

wow, thats good stuff. I didnt realize that guy was a contributor. I am seriously thinking about doing this though. I think i might wait til i am done with school though. I could totally see this taking up a lot of my time lol

-

I came across this tutorial while looking for info on molds and expandable foam. It is so extensive I almost want to try it! http://www.artbrushlabs.com/custom_lures/moldplanning.htm This guy was featured on a plastics website that does tons of molding stuff.

-

You can goto makelure.com if you want. Larry will show you even how to use it. there are a number of place to get it though. i think i remember someone saying you need 16lb. expanding foam or higher

-

Well, the hardest wood I really use is poplar. I wanted to steer clear of traditional router because the baits I make are usually smaller. I really dont want to lose a finger tip and I think the dremel is just a lot safer. Owell, i guess i will just have to think on it more. Hazmail, what shaft size are the lami routers?

-

I have recently made my own router table for my dremel. I have seen the type of bit that dremel sells, and I am not impressed. I wanted to try and get or make a bit that would do a 1/2 or 1/4 round over, but they only have a 1/8". I have already but a dowel on a bit and lathed a round over attachment out of wood. The only thing is, I epoxy'd sand on to the wood to make a grinder, and when I used it, the sand came off. So now I am stumped on how to make my own round over bit for my dremel router. I dont have access to any metal lathing, and would suffice for a sander/grinder. Does anyone have any ideas on how to make something a little better then a wooden sanding bit? Or you think I should try a different way of attaching sand to the bit?

-

Some people have used dip nets from pet stores and such, although they have smaller mesh pattern, they mold well around a bait. You can look at michael's if you want, they have a lot of fabric. I wouldnt buy anything to rigid though, some plastic meshes dare to pliable.

-

Well, some people have made them out of wood, but if your looking for the hair type stuff, it is called friskets. I believe you can get it from fly fishing suppliers.

-

I was thinking about the surface tension also, I think it should work really.

-

same here, I think everyone uses lexan. Except for a few that expirament with some platic from there tackle box dividers!

-

as far as rubber bands holding lures on a turner, here is a link with a photo.lure turner it will hold the joints open. I would really only recommend it if you are coating the linkage with some rubber masking or something since the topcoat with lock your joint. I prefer to do what others say, paint and clear coat separately. i usually use a pin and eye screw joint, so you can top coat the section with the eyes, then the section with the pin(minus the pin), and then put it together sealing the pin hole with your topcoat.

-

I used to hand paint a lot of mine. There are stencil brushes and sponges that you can use. You have to keep em pretty dry to get the effect you want. They are called "stencil brushes". Worth a shot if ya want to try, they are inexpensive. If you do decide to use it, keep a piece of paper handy to work some of the paint off the brush before you go to the lure. You can even use the netting with some brushes, just have to make sure it is secure and wont move. i would recommend a clear coat before starting definitely. I washed off a few before I got some desired effects.

-

-

A lot of people use contact cement. I am not sure how smooth it really matters, other then the imperfections will show through the foil. When I foil I just use a spray adhesive and rub out the foil. I would say contact cement though, seems most use that.

-

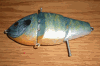

Ok, thanks for more input. I am going to try a few different things. I didnt test it with the hooks and stuff on. I kind of modeled this one off of one of Fatfingers shads based on the my lip angle and design, but I had just looked again, and his belly is a little deeper and it has flat sides. So, I got some things to work with. Man there is a lot of stuff to this! lol. I am more use to making little flat sided ones with circuit lips. I guess I will work on some bigger baits with you guys suggestions. Thanks!