JD_mudbug

-

Posts

419 -

Joined

-

Last visited

-

Days Won

55

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Posts posted by JD_mudbug

-

-

That Ditto bait doesn't look like their regular eel which has the serated-type tail and ribbed body. Most of their baits are not smooth like that one. I have heard about Ditto’s Verifier but have not see one. I have also not seen a Ditto Cutthroat worm nor his DW worm. The bait could be one of those.

Ditto also made:

Gator tail worm 5-1/2” and 7”

Fire Claw (crawfish)

Eel and Baby eel (have ribs/grooves on the body and ‘serated’ gator type tail)

Sizzler worm (reminds me of a Creme scoundrel)

Whip worm (4” and 7-1/4”, looks like a Slider type worm)

Ditzit claw (creature bait, forerunner to the Brushhog type baits but with claws on the end of the center legs)

Dragontail lizard (lizard with stumpy legs and a gator worm type tail)

Chunky (chunk style trailer)

Fat grubs

Tube (solid tube bait)

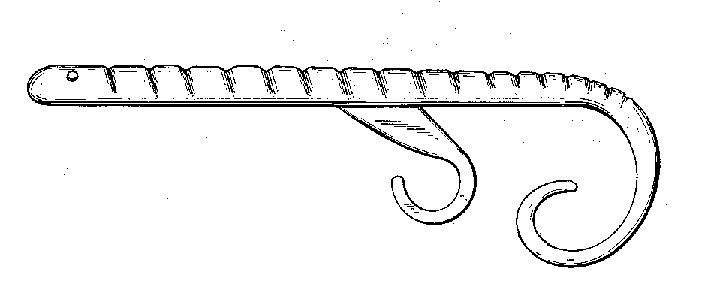

Topwater worm? Not sure of the name. (one curly appendage off the middle of the worm plus the curl tail. See pic. Don’t know if it was actually sold or if it is the Verifier, Cutthroat or DW).Squarehead paint, you might want to reach out to Longrodder over at Bass Boats Central (bbcboards.net). I think he is Bobby Ditto’s nephew. He might be able to identify that bait you have.

-

-

I wouldn't mind a narrow spray replacement nozzle. I don't know if the Liquitex caps would fit on a Rustoleum or Krylon rattle can. The Liquitex is a water based paint and the rattle cans I already have are oil/solvent based. If the cap did fit on my existing cans, I don't know if a narrow nozzle designed for water based paint would get clogged if used on an oil/solvent rattle can.

-

The keys to a rattle can paints job are keeping the nozzle at the right distance and proper angle to the bait. You want to hit the proper areas with the right amount of paint and move the nozzle on the next pass changing the angle slightly to get some blending. Start your spray before the lure, use a straight steady sweeping motion that maintains the same angle and distance to the bait, stop the spray after passing the bait. Any splatters that fly from the nozzle at the start or end of a spray will miss the bait.

You have to use tape, stencils or items like a large comb to get detail. The volume and area of spray from a rattle can is too great to get fine details without something to block off some of the bait’s surface. You can also use rattle can to do the bulk painting and then use a Sharpie, hand painting or air brush to get details.

Big Epp is right about scales. You have to be particularly careful with the nozzle distance when using a mesh scaling. The finer the mesh material the further away the nozzle has to be from the bait. The mesh should be clipped/clamped fairly tight down the full length of the bait. You may have to do several light dustings with a time gap between them to prevent the mesh from getting too wet or saturated. You may also have to tape off the belly if you don’t want the scale paint to hit the belly. The nozzle might have to be so far way that very fine paint particles can drift back onto the belly even if not facing the nozzle.

I have not seen paint throw off the balance of a lure. It would have to be a suspending jerkbait, glide bait or finesse type crankbait like a Shad rap 5 for the paint to have a chance to throw off the balance. A heavy clear coat like D2T would be more likely to do that. I have painted some baits with the thick liquid Rustoleum and they work fine.

I have found rattle can skills do not really translate into airbrush skills other than visualizing the overall paint scheme to be achieved. Good airbrush technique is nothing like using a rattle can. I keep using rattle cans on some larger baits because I can get cans for $2 at a local discount tool store.

-

1

1

-

-

These posts might help. From what I understand, the site did not use any user info from before August 16, 2021 to calculate rankings when the site moved to a new server.

https://www.tackleunderground.com/community/topic/38179-badges/

https://www.tackleunderground.com/community/topic/38101-upcoming-server-migration-please-read/

You get points for posts and likes made after 8/16/21.

I also suspect any reference in a post to Blazing Saddles, History of the World Part 1, or Spaceballs earns bonus points.

May the Schwartz be with you.

Jim

-

3

3

-

-

Most of the standard Rustoleum and Krylon seem to be oil based or solvent/synthetic based that float. The standard Rustoleum in my area is the white can that says Protective Enamel on it somewhere. The Krylon cans come in a bunch of colors. The Colormaxx ones are what I usually find in my area. That paint also floats. At least, the 20 or so cans I have in those product lines float.

Marking paint and Fabric paint seem to be usually water based. They don't want oil based paint used to mark the ground to seep into the groundwater. They don't want a canopy or outdoor furniture to burst into flames because some dope put it too close to the fire pit.

If you can't find the base info on the can, I look up the particular paint up at Walmart, Lowes, Home Depot websites. They usually list it in the product spec down near the bottom before the reviews. Or, like Mark says, you can do a small spray into a disposable cup filled with water to test it.

-

1

1

-

-

Most of the rattle-can paint floats as it is oil or solvent based. You can spray it into a bucket of water to make hyrdo dipped swirl paint jobs. There are some water based spray paints like the spray paints for outdoor fabrics. The water based paints may float, sink or even suspend depending the ingredients.

https://dipdoctr.com/best-spray-paint-for-hydro-dipping/

https://www.youtube.com/watch?v=kHoW-56NGVU

-

2

2

-

-

I think the action is more important that the paintjob. I don't try to get a picture perfect type paint job. I have posted 3 pics in the Hardbait gallery showing about 20 paintjobs done without an airbrush.

-

I use rattle cans, mostly on larger baits. I use 3M blue 2080 tape that comes in 1/8” and ¼” wide rolls for getting fine lines. The tape is easy to curve and has low adhesion so it doesn’t ruin underlying paint if dry. After doing a few baits, I have gotten fast at taping off things life perch stripes and fins.

https://www.grainger.com/search?searchQuery=3M+2080+tape&searchBar=true

I use netting, tule, window screen, Walmart lingerie laundry bags for scales. The laundry type bags are thick with larger openings which are great for larger lures. I use stencils as well. I just use a mix and match approach to what I think works on a bait. You could try liquid masking tape/art fluid masking. I have just started using that. You can also use Sharpies with different tips for fine details.

In addition to starting the spray before the bait, another key is not to get the can too close and do a couple of light passes. If the paint goes on too heavy, you can get a paint ridge at the tape edge or a paint run. On areas like a gill plate, you may want the paint ridge. No doubt an airbrush is better than a rattle can. With a rattle can, it would be difficult to get a ‘work of art’ paint job. But, you can definitely can get a quality paint job that will fool a fish.

-

2

2

-

-

My only snakes had a jitterbug type lip. The only ballast I had was in bottom of the head at the half way point and a smaller ballast in the second section. That placement won’t work on yours as that is where the lip is. My lip was in front of the body. Most of my other wake baits are 2 or 3 sections and the ballast only goes in the head section between the lip and the front hook hanger. They have a much longer front section than you snake does.

I would get your joints, line tie and hook hangers mounted. Then seal it. You can hold the lip in with tape and glue ballast weights to the belly to test it. I test with sections of coil lead off Amazon. That way I can drill holes sized to the diameter of the lead once I know the right placement.

https://www.amazon.com/gp/product/B003OCAFEC/ref=ppx_yo_dt_b_asin_title_o07_s00?ie=UTF8&psc=1

You may need some ballast before and after the lip in the head section because that section is so bulbous, a smaller ballast in the second, and an even smaller ballast in the third. It will also depend on hook placement.

Your bait looks great so far. I would want to test it before drilling holes into the body especially after all that hard work in carving.

-

1

1

-

-

I have made numerous Shellcracker type baits as well as 2 and 3 section baits that are 6 to 10 inches . Yes, that type of tail will work with the serpentine action of the bait. The tail fin itself is not jointed. The tail fin is one piece with 2 holes for mounting. The holes in the fin have to be bigger than the cross-pins so the tail will flop loosely back and forth on the pins. I use small wire nails for pins. If you stop the video at 12:28 and 13:07, you can see the holes. Sometimes, I just make one long rectangular hole vertically in the fin instead of the 2 holes. When the bait swims, the actions carries on to fin which flops back and forth. It gives the effect of an extra joint. I like that type of tail kick.

I have gotten away from using Lexan fins. I like somewhat flexible fins that will bend over when a fish bites. I make my flopping-type fins from silicone mats (placemats, cooking mats, under sink mats) and plastic containers (milk jugs, coffee can lids, food containers, notebook covers). You still get the kick with Lexan as long it has freedom of movement on the pins and is not too big in relation to the size of the bait.

Jim -

That's what I usually do. Fit it with tape on the part of the lip that goes in the slot plus a piece of tape on the backside of e lip to the body. If the lip is aluminum, I use some hot glue where the lip comes out of the body. The glue peels off with an Xacto knife. I have lost a couple of aluminum lips with just tape.

-

Engineered Angler, Marling Baits, TreysArt, zimmtex use twist eyes in some their builds. Engineered Angler has a bunch of vids on twist wire eyes.

I wing most of my builds. I test the lure after sealing with hooks that have points bent over. I hot glue or tape any diving lip in temporarily. That way I can try different lips and adjust ballast if the lure is a dud. Once the lure works, I paint it.

-

1

1

-

-

There are plenty of posters here with way more knowledge than me. Before using TU, I primarily learned from failures, of which there were many. Having a bait break on a fish can sting for a long time.

Some recent posts with good info on wire.

https://www.tackleunderground.com/community/topic/38342-hardware-for-wooden-hardbaits/

https://www.tackleunderground.com/community/topic/36632-wire-size/

I use stainless safety lock wire in .041 for typical bass baits like a 2.5 square bill and .051 for most everything bigger than that. I go up to .062 on larger lures 2.5 oz and up.

I no longer use anything under .041 for hardbaits. I don’t think anything thinner than that would hold up to pike or musky. 20 gauge is .036”? I think snare wire might be more pliable than safety wire. You may get a pike landed but the lure may not survive if a wire eye gets tweaked and you have to bend it back. Hard baits are not like an inline spinner that can just be re-shafted. I have had a few baits with .035 that were one pike and done. .035 is fine for small baits where there is no pike or musky.

Malin and Wire & Cable Specialties are the 2 most common suppliers of safety wire. You can find it on Amazon, McMaster Carr, and Grainger. The price varies from site to site.

Yes, you can buy straightened wire. Sometimes it is called wire shaft(s). Sometimes you find it under wire forms or pre-cut stainless wire. You can find it with a closed loop, open loop or no loop. LPO, Janns, Barlows, and Musky Shop carry it. You can find it on eBay and Amazon too. This wire is not annealed and is stiff and harder to bend.

https://www.lurepartsonline.com/search?keywords=wire%20shaft&page=1

-

You can go the LPO, Janns, Barlows route. Check Michaels and Hobby Lobby.

I have bought some from Rock Island on eBay. There are a bunch of sellers on eBay.

Countbass has hollow metal beads.

Beadwish for eyeball beads, letter beads, pearlized type beads, and a bunch of other type of beads.

https://beadswishdiy.aliexpress.com/store/4475072?spm=a2g0o.store_pc_groupList.pcShopHead_9741685.0

You have to make at least one spinner with your name or initials in it. I found a big box of assorted colored letter beads at Walmart.

-

I use the stainless shaft wire from LPO, Janns, Barlows, Musky Shop on some builds, particular those with a rotating blade(s) or body section like a plopper, globe, or prop bait. You want shaft wire on these baits because it does not bend easily which will keep the body section or blade spinning. You can get the shaft wire with a loop on one end from the component suppliers to save some work.

I use stainless safety lock wire from Malin or WCS (Wire and Cable Specialties) on other builds where I don't need a shaft wire. This wire is annealed making it easier to bend. I have also built a few with wire from AFW (American Fishing Wire).

I just search for wherever I can find best price on the diameter I want. Sometimes the best price is on Amazon or eBay. Sometimes the best price is from an industrial supplier like McMaster Carr or Grainger . I will stock up when one of the lure components places has as sale and free shipping.

-

I have made some 2 and 3 section swimbaits that are wire-through. There is no easy way to do it. It does get easier the more you do it.

What I do is cut a slot down the center of the belly of the sections. Make a line tie loop in the wire. Add a dropper wire or swivel to that main wire. You may have to drill a hole to just past the bottom of the slot for the swivel/dropper wire to fit. Check the wire in the slot for length and mark where it exits the back of the slot. Bend a horizontal loop at the end of the first head section starting at the mark. Test fit the first section harness, adjust/ re-make if necessary. Once the fit is good, I lock the wire in the front section with epoxy. Then, I fill the slot with epoxy/superglue coated flat wood stirrers. Run some sandpaper by hand over the stirrers if necessary to get them in the slot. I like to fill the slot with the same material as the body.

Once your front section is set, you can make the wires for the next section. The next section should start with a vertical loop unfinished. Just make the loop and don’t do any wraps to close that loop. Add dropper wire or swivel if necessary. Finish the wire with a horizontal loop in the back towards the tail if adding a 3rd section. If the second section is the last, make the last loop whichever way you want it. Test fit and adjust/remake as necessary. Once you have the length right, slip that section’s wire front loop onto the back loop of the head section and complete the wraps to link the 2 wires. You can then slip the second body section’s wire into its slot. Epoxy the wire in. Fill slot with wood as above.

Repeat the same procedure for following sections. If the last section has no hook and just a mounted tail fin, there will be no pulling on it. You can use a long screw eye/twist wire eye if you want to avoid cutting a slot in that type of section.

You complete one section at a time. Test fit, lock the wire in, fill the slot and move onto the next section. That way if you screw up, you just lose a bit of wire. The loops in between the sections have to be in opposite directions, horizontal vs. vertical, for them to move. Once you have the wires installed and slots filled, you can do ballast testing and drilling ballast holes. Just don't drill deep enough to hit the main wire in the sections.

I hope that helps. My first one was a bit of pain. After a few, I can do them fairly well. It sounds more difficult than it is.

-

3

3

-

-

I bend heavy wire the same way as you do, Outlaw4. I use Knipex round nose pliers model 22 02 160 to make the loop. Salty recommended the 22 02 140 in one of his older posts. I couldn't find that size plier and got the next size up in length which is the 160mm plier. The 140mm makes a 7/64" loop and the 160mm makes a 1/8" loop. You can make a smaller loop by using the Knipex to form the loop and then squeezing it with normal pliers.

-

I forgot to mention using cross pinning to secure hardware. You can make a piece of wire with a loop on each end or use a swivel. Then put a piece of shaft wire perpendicular and through the loop end in the bait. I have used a through-wire or a wire for a joint to cross pin a swivel for a rotating belly hook hanger. You can cross pin your diving lips for added security too.

We have some tiger musky in my area. They get crazy when landed much like their northern pike half. A death roll in the net where one hook is in a net hole can be a mess. You definitely want more of a mechanical bond like Outlaw4's method or through-wire if you hook into one of them.

-

3

3

-

-

I would trust the epoxy over the super glue and baking soda. The super glue and baking soda combo make a great body filler but I am not sure of its holding strength. 20 lbs may seem like a lot but it is really not. The torque a big fish can put on eyelet can be more than that. The fish can use the lure's weight as leverage to snap it back and forth. A fish thrashing in a net can also put on tremendous stress on a lure. It depends on the size of the fish you are targeting. Some of the waters I fish have big pike and musky. 20 lbs wouldn't cut it. EA was getting 160+ lbs on pull tests with twist wire and epoxy.

As for tallness, I think of it as more a question of the weight of the lure. A 6 inch minnow would be 1 to 2 ounces. I would use .051 wire for that. A bluegill bait of the same length would depend on the weight. Once the weight gets over 2.5 oz, I would start looking at .062 wire. It could also be a combo of wire. If I was making a big 'Shellcracker' type bait with a joint, it could be .062 for the line tie and .051 for the joint loops as there are two of those to share the stress. The pin that goes into the back section and through the 2 loops would be .062 shaft wire, a cut section of a stainless nail, or heavier stiff wire like a stainless toy car/plane axle. You do not want a hinge pin to flex.

https://www.amazon.com/gp/product/B08L7RKM6Q/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

On large baits, it don't use woods like balsa. I use cedar, poplar, and PVC. So, density is not an issue. Also, the baits are big enough that if I am using twist wire eye I can get the twists an inch and a half into the bait. The twists give a ton of surface area for epoxy to bond it to the lure.

If I am using less dense wood like balsa, I would keep the wire diameter appropriate to the size of bait and try to get in longer screws or just make it wire through. You want to reduce the chances of failure as much as possible. That failure could happen on the fish of a lifetime. A failure like that will sting years later.

When I make a twist wire eye, I file the end to a point. Filing takes a minute and prevents the flared cut ends from widening the pilot hole. I drill a pilot hole the same size or slightly smaller than the twist eye. The twist wire screw acts like a normal screw with a reversed thread. I can screw the twist eye into the hole with counterclockwise turning. I test fit it to make sure I have the length right, unscrew it with clockwise twists, and pump epoxy into the hole with a disposable plastic syringe, baggie with corner cut off, or pushing epoxy in with a tooth pick or scrap wire. I then coat the twists with the epoxy and screw the twist eye back in. They max out my 50 lb. fish scale and then some.

-

2

2

-

-

I mostly make baits 5+ inches in length and 1+ oz in weight. I use .051" for them. Sometimes, I will go with .062" on lures of that size if they will used for pike/musky.

For larger lures, when the bait is 7"+ and 2.5+ oz, I use .062.

For a typical bass-size crank, I use .041".

-

1

1

-

-

Welcome to the site.

On larger pike/musky baits, I will use a straight wire through from line tie to tail hook with dropper wires or swivels for belly hooks. Through-wire is the strongest. I sometimes use wire-through on smaller lures with less dense woods like balsa because it has less strength to hold a screw.

For non wire-through baits, I like stainless safety wire twist eyes the best. I set them with epoxy. Epoxy is stronger than super glue in holding a screw. I put them into the bait at angle. I angle the line tie wire and tail twist wire up towards the top of the bait. I will put the belly twist wire in at angle wherever it will fit, but prefer it to be angled forward. I have yet to see a wire twist eye set with epoxy fail. Engineered Angler has some videos on screw vs. twist wire and epoxy vs. superglue that are real informative.

https://www.youtube.com/watch?v=YDNXd8ILnJ0&t=34s

https://www.youtube.com/watch?v=fIEhsMILC08

Next, I like the .072 and .092 stainless screw eyes. When I use these, I set the eye of the screw into a recessed cup in the lure body a bit. I can fill the recess with epoxy to reduce the chance of the eye opening up by making sure the part where the eye could open is embedded in epoxy.

I would be worried about a cotter pin with superglue. Cotter pins are fairly smooth. I think a big fish could pull them out. If I were to use cotter pins, I would score the end going in the lure body and set it with epoxy.

-

3

3

-

-

Welcome to the site.

I use the Lure Parts Online .072 and .092 stainless screw eyes on some baits.

https://www.lurepartsonline.com/-092-Magnum-Screw-Eyes

https://www.lurepartsonline.com/Stainless-Screw-Eyes

On others, I make twisted wire screw eyes from Malin or US Wire and Cable stainless safety lock wire from Amazon. 041”, .051”, and .062” depending on the size of the lure.

I twist the wire with these 9” pliers.

As for wood, I get pine, Western red cedar, and poplar for the big box hardware stores. I comb through the piles for the best pieces. I pick up other wood where ever I can find it – fallen branches, discarded furniture, handles from broken tools, craft stores. For balsa and basswood, you can try online craft sites and amazon.

You could also try PVC boards from the hardware stores. There is an excellent post pinned near the top of the Hard Bait forum.

Jim

-

1

1

-

-

I no longer use piano wire for bass. It gets mangled too much.

As for the dimension size of the frame, I use small frames for bass in a few situations. One is early spring when there are lots of small baitfish. I have made some small Pond Magic type spinnerbaits to match the small baitfish. The other situations are water coverage and deep 'cranking' situations. I make a Rocket Shad type small frame heavy head spinnerbait for those. I use stainless wire on those small frame baits.

-

1

1

-

1

1

-

Glitter

in Hard Baits

Posted

I use Krylon Glitter Blast rattle cans with good success. Start spraying 1.5-2 feet from the bait to see the coverage and move in as necessary to make the glitter denser.

I have also used FolkArt Extreme Glitter 2796E Hologram which is a brush on glitter on white baits and it ends up looking like the old G-finish lures. I have not tried the other colors in that product line.