JD_mudbug

-

Posts

419 -

Joined

-

Last visited

-

Days Won

55

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Posts posted by JD_mudbug

-

-

I tie to the lure's split ring on suspending jerkbait like a Vision 110. When I have a lure that suspends well, I don't want to change that with a snap. I don't want to change the angle jerkbaits sit in the water either.

On other lures, I use a snap. I will use the snap type like Mark does. The closing end on those types of snaps hook around the side wire and end inside the outer frame of the snap. Nothing for them to catch on. I have yet to have one open. I like the Decoy Egg snaps as they are round at the lure nose tie. Owner makes one too.

https://www.tacklewarehouse.com/Decoy_Egg_Snap_7pk/descpage-DEGGS.html

Tying knots can be difficult in rough water, high winds or cold weather. I don't want to waste time struggling to re-tie when I need to change lures.

Snaps can weaken over time from opening and closing. I toss my used ones after a while.

-

1

1

-

-

Sorry, I thought you were talking about the dulling.

Chris is right. I use the floor wax right after the reflective finish, paint the back/belly/details, and top coat with a 2 part epoxy. Lately, I have been using D2T.

-

I have not used nail foils but I have used various foil tapes, adhesive craft and fishing lure foils, foil skin lure wraps, and assorted chrome, metallic, and mirror paints. They all go dull to some extent. You may want to try floor wax to coat the lure after foiling. I have only used wax a few times and it does keep much more of the reflectiveness.

https://www.tackleunderground.com/community/topic/38203-chrome-paint/

-

1

1

-

-

It is silicone tubing cut into sections.

LPO, Janns, Barlows have the collars.

https://www.lurepartsonline.com/01-Regular-Skirt-Collars

https://www.jannsnetcraft.com/skirt-collars-rattles/345431.aspx

https://barlowstackle.com/regular-skirt-collars-b/

You can also find them on eBay and Amazon.

If you are talking about getting a length of the tubing uncut, I don't think I have seen tubing with the same wall thickness as a skirt collar for sale. You can find various diameters of silicone tubing on Amazon. Most of the uncut lengths of tubing are thin-walled.

Just an observation - I avoid the clear collars and the transparent amber or 'natural' ones. Those collars seem to break down faster once exposed to to sun and water. The solid color ones last much longer. Plus, the solid ones usually get gummy and stretched out before they fail. You can see when they are about to fail and can re-band the skirt. It's tough to tell when the clear or transparent collars are about to fail sometimes. You usually find out when there is a pile of skirt strands at the bottom of the storage box.

If you are looking for a specific colored collar and can't find it (for example blue), you can use a white collar and color it with a Sharpie. The color lasts for a long time.

-

Thanks for posting this. I have a couple of Magdrafts and did not know the wire was open like that and could pull out.

I have to do the same type of thing to R bend spinnerbaits in pike waters to keep the leader from sliding down the bait's wire. This spring from a pen is a creative solution.

Now, I have to be wary if another angler asks to borrow a pen.

-

1

1

-

-

The lifting sounds like something was still off-gassing. Did you use a sealer on the bait before painting? The sealer may not have dried completely but the paint on top of the sealer did. There could be moisture in the wood that escaped after the paint has dried. The moisture is trapped underneath the paint and works its way out. You may want to dry the wood in an oven before sealing.

The lifting by itself could have been something on the paint like fingerprint oil that prevented the clear coat from sticking. You have the cloudiness and the lifting which most likely means a moisture issue. It has to be in the wood or from some other step along the way. Something was not completely dry before the next layer was added. In addition to drying the wood, you could hit the bait after the sealer has dried with a hairdryer and let it sit some more, and hit each layer of paint with the hairdryer too, just too make sure you are not covering something not fully dried.

I get the cloudiness sometimes when I clear coat a bait on a rainy day. The key is to be lucky and have it happen on a white bait.

Most resins can take a lot of heat once cured. It would have to be extreme or open flame. I don't think the heat from being in car would be enough. You can try to find out what the temperature range for the resin is. See if there is a Technical Data Sheet and Safety Data Sheet for the product. What usually happens with the heat is the moisture trapped in the wood, sealer, base coat paints, etc. get turned into vapor faster causing the lifting and cloudiness. If the resin is heated too much during application, it usually kicks off before you can apply it and is filled with air bubbles. The runaway kickoff reaction usually gives off a bad smell. I once used a torch excessively to pop the bubbles in the resin after mixing. I started to smell it and tried to finish applying it. It kicked off as I was applying it and the brush got stuck to the lure.

-

Hi Lochie,

I take it you still haven't found a good clear coat in Australia.

The cloudiness could be amine blush. If the resin is fully cured, try wiping the bait down with rubbing alcohol or warm soapy water and then pat dry to see if it helps. It can occur in cool or humid conditions or from the bait not being completely dry. You may want to heat set the paint with a hairdryer or heat gun on low. Maybe wait 1-2 days for the paint to fully dry before applying the resin. You could also need a dehumidifier. Check the preferred temp range and humidity for the resin on the package or company website. You will get more help if you tell the resin used or other details on how it is mixed, applied, rotisserie or not, etc. There might be someone on here using the same product.

https://www.tackleunderground.com/community/topic/36592-epoxyd2t-issues/#comment-298961

By blutches do you mean air bubbles or thicker uneven lumps of resin? Thick uneven resin could mean it is curing before it can level out which could also be a temperature/humidity issue, rotisserie speed is too fast or too slow, the lure is flipping suddenly on the rotisserie usually at the top or bottom of the rotation, or too much resin is applied to the lure. You may also need to thin your resin a bit with a few drop of denatured alcohol.

Air bubbles can be from mixing too aggressively or with something that is more likely to introduce bubbles like a wood stick. You can mix with a plastic mixing stick and quickly pass a torch over the resin to pop the bubbles after mixing.

Below is a collection of posts some of which you may have already read. I threw them in here just in case. Lots of good info about clear coat issues.

https://www.tackleunderground.com/community/topic/37686-tacky-epoxy-check-your-temps/

https://www.tackleunderground.com/community/topic/37532-new-guy-old-questions/

https://www.tackleunderground.com/community/topic/12510-trying-to-achieve-a-flawless-finish/

https://www.tackleunderground.com/community/topic/38177-resin-clear-coat-problems/

Jim

-

2

2

-

-

The Jann's chart has 2 bodies figured in. One is called the head. The head is a small body, usually pointy at the top and flared at the bottom, that goes on top of the body. It makes using the chart difficult. You will have to use lower common denominator addition to get a total body weight of the head and body. Plus they could be using all solid beads which for me is too pricey.

The thing I use most on the Jann's chart is the total weight. I bought a cheap ounce and gram digital scale on Amazon. A scale is useful to double check the listed weights of the component. I sometimes find the listed weights are off. I put everything on the scale - blade, beads, shaft, clevis, treble hook. That will leave the body to get to the total weight. I use hollow or plastic beads except for a small solid metal bead below the clevis. For a 1/4 oz spinner, I throw everything on the scale and usually need a 1/8 oz weight body to get to near a 1/4 oz total weight with the listed components on the chart (#3 blade, #2 clevis, shaft, beads, #4 hook). This gives you a baseline. A range of weights will work and everyone has their own preference. With a scale, you can drop down body weights, add additional beads or a head body, swap in a different hook sizes to see how the various components effect total weight. Then you can keep notes to which ones you like. You will not get a specific answer as to what is going to work best. It depends of the body of water, depth, weather, species of fish etc. It's why I have a range of different weight spinners for a given size.

I make my spinners heavier than Azsouth. I typically use 1/8, 3/16 and 1/4 bodies which are typically weights either brass, lead or tungsten.

My typical #5 iline is a 1/4 oz or 7 gram body, .035 or .040 shaft, 1 small solid bead, 1-2 hollow or plastic beads, and #2 treble for a 1/2 oz total weight. I have made #5 spinners with 1/8 oz bodies to a full 1 oz body and they all catch fish. They just run at different depths. If I mark fish in 10 feet plus, I will going with the heaviest spinner. If I am fishing shallow or from shore, I will start with the lightest one.

-

Safety-pin spinnerbaits are nice but pre-made heads can be hard to find. I also don't pour lead anymore. LPO used to sell spinnerbaits heads where you could pick the wire form, head mold, and hook. You had to order a minimum of 25. I have done that in the past. I could not find that on their website anymore so I think they no longer do that. You might want to email them or one of the other places that sells spinnerbait heads if you want safety-pin heads.

I am like Cadman. I use R bend for bass. I use loop wire for pike, musky, and saltwater. If I want to use a R bend in those situations, I will use small piece of latex tube or a small o-ring on the R bend to keep the line or leader from moving.

-

1

1

-

-

+1 for Titebond.

It usually costs a bit more for Titebond III but it's what I use. Titebond III is slightly stronger than II and rated as waterproof. Titebond II is rated only as weatherproof/water resistant. For a 16 oz bottle, Titebond III is $1-2 more at around $8. Titebond III does take longer to dry, 10 minutes as opposed to 5. Both II and III are good enough for regular size baits. For big baits, saltwater, musky/pike, I would use III for the slightly more strength and better holding up to water penetration which is more likely in those situations.

http://www.titebond.com/community/the-big-three

-

1

1

-

1

1

-

-

If you have spare cheap blades, it doesn't hurt to try anything. I would try narrowing the top first. If I were to try modifying the bottom, I would first try to blunt the blade at the very bottom, flatten that curve a bit. That might make like an Indiana. I think if you narrow sides at the bottom that will probably cut lift. It would be more like a willow.

-

1

1

-

-

I don't know. Do you mean filing down the edges of the top quarter of the blade to make the end where the hole is more pointy? I haven't tried that.

I am not a vortician, a vortices expert. My guess is that could cause the blade to flare out wider away from the shaft which should give more vibration and probably slow the spin rate. It could cause the finish to break down faster. On a steel blade, you could end up getting rust. Might be best to try that on a cheap brass blade.

Somewhere in my storage I have the blade from a Mepps Double Cross spinner. The blade is made up two overlapping half blades joined by a rivet that is set into the hole. You can adjust the flare on the blade by spreading apart the halves. The theory was having one spinner blade that would act of as different blades. That spinner never seemed to catch on. My got relegated to storage after the shaft got mangled on a snag.

-

1

1

-

-

Four different #3.5 willow blades.

Left to right are: LPO fish scale, LPO economy painted, LPO fluted, and Aliexpress on the right. The Aliexpress blade is steel.

The fish scale and the chart have the same length and width. The fluted and the Aliexpress blade are the same length, both of them being shorter than the 2 on the left. The fluted is the narrowest followed by the fishscale and the chart blade. The Aliexpress is the widest and is almost an 1/8” wider that than the fluted at the midpoint from top to bottom and has the most cup. The fishscale has a curve from the eye to the tip that when sitting flat on a surface there is a gap under the middle. It is the only blade not to sit flat around the edges.

I have not tried the Aliexpress blade yet. I cannot tell the difference in vibration between the other 3 as those don’t produce any noticeable vibration. The fishscale does seem to spin the easiest. I expect that the Aliexpress blade might actually give off a vibration due to the width in the middle.

-

1

1

-

-

Here is a pic of some different #5 French blades so you can see the shapes.

From left to right are LPO regal black nickel, Aliexpress, Mepps Aglia, and Mepps Black Fury which has a ‘Comet’ blade. The Aliexpress blade is steel. A magnet sticks to it. The other 3 are brass. I have not tried fishing with the Aliexpress blade yet. The LPO blade is the shortest. The Comet blade is the narrowest. The Aliexpress, Aglia and Comet are the same length. The Aliexpress and the Aglia are close to the same size, the only difference being the Aliexpress gets wider quicker going away from the hole. They all have curved cupping except the Aliexpress blade which has sharp cupping at the edges and a flat spot in the center.

I have fished with LPO regal, the Aglia, and the Black Fury/Comet. If I had to rate vibration, Aglia was first, LPO regal second, and Black Fury last. That is also the order of the running depth with Aglia being the shallowest and Black Fury being the deepest. The different shapes have lot to do with it. I also think the pointiness/bluntness of the blade by the hole has an effect too. The Black/Fury Comet is very blunt by hole and seems to spin close to the wire compared to the Aglia and LPO. The LPO regal has the nicest reflective finish, followed by the Aliexpress, Aglia and Black Fury. The Black Fury does more of a strobe as opposed to a flash with the fast spinning dots looking like perch-like stripes. I can’t attest to the durability of the Aliexpress blade. The other 3 have been durable. Those 3 blades I have fished with have all worked. I have caught fish on all of them. They give you different options. The Black Fury/Comet blade is the hardest to feel in the rod tip.

I will be testing the Aliexpress blade as soon as the weather gets better. The lakes are frozen but the rivers and streams are still open.

-

A 5 to 10 lb bass would be a nice battle on a ML rod. We don't really get any bass over 10 lb where I am (10-8 is the NH record, 10-4 is the VT record). The biggest bass I have caught have been 8s. We have many pike over 10, plenty in the teens, and some break 20 lb. I also fish some waters with Musky but they tend to be smaller and far less numerous than the pike. Some waters have walleye with plenty over 5 lb and occasionally some over 10. Longnose gar and bowfin can also hit double digits but I have not hooked into a big one of either of those species. I have caught smallies, largies, pike and walleye on #5 spinners. I can't use ML rods in those waters. Even a Medium rod usually doesn't cut it. Pike and bowfin can be crazy during the fight especially when they get close to the boat. Compare the weight range of the rod if listed to your #5 spinner's weight just to make sure it is not overtaxed.

-

1

1

-

-

That medium light rod might not have enough backbone for that spinner with #5 blade and 3/8 oz body. I throw something like that on a medium rod, MH if pike are around. Are you using a fast action or moderate action rod? I find on the bigger spinners that spinnerbait/crankbait type rod with moderate action helps me feel the spinner more. Maybe switch up the rod action to see if it helps feel the vibration more.

I usually throw inlines on mono unless I am using a weedless swimbait hook inline on braid. I am using 10-12# mono on #5 spinners in bass waters (20# lb braid on the weedless swimbait spinner) . I go up to 14# mono and 30#lb braid when pike are present. 14# mono and 30# braid in weeds will give me a decent chance if I run into a good pike. If I am in pike waters, I will make a leader out of AFW Surflon Micro Supreme 7x7 Camo which is very flexible stainless steel braided wire which you can tie knots with. I will sometimes use a 50 pound flouro leader if the water is clear. I have tried 30# flouro and had bite-offs.

I try to base my spinner weights on what the Mepps weights are. #5 is 1/2 oz, #4 is 1/3 oz, #3 is 1/4 oz. These weights are also the same as in the Janns chart. Sometimes I am a bit heavier than theirs but it doesn't seem to affect the feel of the vibration. There is definitely a range of weight a given blade size will work with. Once you get some .035, you can play with the weights and find what you like best.

https://www.jannsnetcraft.com/content/make_fishing_lures.htm

-

1

1

-

-

Yes, I like to include everything when I weigh the components on the scale. Sometimes the hook can be a decent percentage of the total weight. When you get into bigger hooks and ones with big dressings, they can add to significant weight. It's all sort of a balancing act and you have a range that will work. If you look at what you did with your .030 wire spinner, not only was the body upsized to 3/8 oz, the blade was upsized and the presumably the hook was upsized too. The increase in body, blade and hook adds up to a big total weight increase. On a #3blade spinner, I go with a #4 treble if in bass waters and a #6 if I am going for trout. On a #5 blade, I usually go with a #2 treble. I like my #5 blade spinners to weigh between a 1/2 oz and 5/8 oz total. If I am looking to making them run deeper and cast farther, I will go heavier and that does cut down on the vibration felt in the rod. My #5 blade 1 oz body spinners keep a constant bend in a MH or H power rod due to the weight which cuts down on the feel in the rod. They still catch fish. They run deep and if they weren't vibrating they probably wouldn't catch much.

Like azsouth said, you are talking about the feel in the rod. Just because you don't feel it doesn't mean there is no vibration. Rod length, rod action, rod power, blank and guide quality, line and leader all play a factor in what you feel. Once you try a .035 wire, I would try a lighter 5/16 body. That should put in the ball park for a #5 spinner. Can you post a pic of the spinners? There might be something someone can spot by seeing them. You might be looking at the spinner when you the rod set up could be the issue.

-

2

2

-

-

Yep, the Deep Secret. Probably the deepest diving small body lure.

Speed Trap body, trench digger lip.

There's nothing wrong with casting it once you get past the lack of a weight transfer chamber, some helicoptering, and the lip causing the lure to sail off course in random directions on nearly every cast.

-

4

4

-

-

The wire size will affect rotation if the hole in the clevis hole is too tight and doesn't spin freely. If the clevis is too big it also may not spin. The blade may not be able to spin a clevis that is too big or the wire just rattles around in the clevis holes. Another thing to watch out for are stirrup clevises that are spread apart at the ends. I have some like that. They look like more of an arch shape than a lowercase 'n'. The clevis ends were close to a 45 degree angle to the wire. I had to squeeze the ends together some with pliers to get them closer to 90 degrees to the wire in order for them to work.

If the wire is too thin for the body weight, the wire can flex and dampen vibration. Initially, I made my 1 oz body spinners with .040. The blade spun but I felt almost nothing on the retrieve. When I held the bait by the line tie loop, I could see the wire was bending from the body weight. I switched those to .051 wire which did improve the feel of vibration. Your 3/8 oz body could be making the .030 wire flex. Hold the bait horizontally by the line tie in the side of the vice jaws, slide everything toward the hook like it would be on the the retrieve, and see if the wire sags down.

If you have a digital scale, compare the total weight of your assembled spinners. Compare that #3 blade with the 1/4 oz body to the #5 blade with the 3/8 oz body. That is a big jump in total weight. Maybe try a 5/16 body instead of the 3/8. Look at the weight range for the rod too. It could be the larger spinners are overtaxing your rod.

-

1

1

-

-

I would estimate I use 60% French blades when fishing inline spinners. The other 40% is a mix of inline Panther Martin type, Colorado, Indiana, swing, and willow. I have the most luck with the French blades, especially in multi-species waters.

By 3/8 oz spinner, do you mean a spinner with a 3/8 oz weight for a body or the total weight of the spinner is 3/8? If just the spinner body is 3/8 oz, I usually use a #5 French, #3 or 4 clevis, and .035 or .040 wire, mostly .040 due to pike. If the total weight of the spinner is around 3/8 oz as in a 1/4 oz weight body, I usually use a #4 blade, #3 clevis, and .035 wire.

A #3 French blade would be harder to feel on a spinner with a 3/8 oz weight body. The spinner would weigh near 1/2 oz in total. The bigger the total weight compared to blade, the harder it is to feel in the rod. I bet there is still vibration. It is probably just hard to feel in the rod tip. If the blade spins easily, I would still try fishing it even if you can't feel it. Let the fish tell you if it works. I have a few spinners with a 1 oz lead body and a number 5 French blade. They cast a mile and I only feel the vibration close to the boat. It could also be your rod or line choice. I like to throw my spinners on a 7' to 7'6" rods. The longer rod helps in feeling the vibration. I usually go with medium power rods on the bass size spinners (#3-5 blades). I mostly use mono. On #5 blade 1/2 oz spinners, I use 12 lb. which is usually my default on the bass size spinners. I use anywhere from 6 to 10 lb on trout spinners (#0-3 blades). I will use braid when throwing a spinner with a belly weight swimbait hook and plastic trailer in weeds for hook-setting and cutting through the weeds.

Also, if you get your blades from different sources you can check your blade widths. The LPO catalog has a blade size chart in the back or you can check the blades against any Mepps spinners you have. A size 3 from one place could be narrower than another brand's size 3. I have found some French blades that were narrower than a traditional French Aglia-type blade. The narrower French blades act more like a willow or swing blade (less vibration, more rotation and flash). These narrower French blades are more like the Comet-type Mepps blades.

https://www.mepps.com/mepps-tactics/article/why-different-blades/421

-

Matt,

If you buy them in person, hold the bait up to a light and look for fisheyes on the lip. I have only found 2 new ones with fisheyes. I never noticed the fisheyes until I compared the old vs new baits. The new baits with fisheyes on the lips also have a small fish eye or 2 on the body towards the tail which can be hard to spot on the busier paint jobs. I often forget to look over baits in a store before I buy them. I never bothered to touch up the clear coat on those lips, but I did on the body fisheyes to protect the paint. Most of the new ones are well made. The body dents, even the large dents on the old baits, don’t affect the action.

Mark,

I remember your Speed Traps. They are impressive. Your pumpkinseed paint job on one of those would be deadly. Did you use polycarbonate for the lip?

For more authenticity, you could have carved in a molding dent.

When I find a lure I really like, I tend to buy a lot of backups. So, I have not had the need to make one yet. Over the past 5 years, I have started doing more pike/musky fishing. So, I have been making mostly larger hardbaits, inlines, and spinnerbaits. At some point, I plan on attempting a bigger Speed Trap that keeps the same tight wiggle.

Happy New Year,

Jim

-

- Popular Post

- Popular Post

This is an update to an older post. It is long so I made a new post.

Luhr Jensen Speed Trap – old vs. new, and the new Norman Speed N.

Pre-2006 Speed Traps were made in the USA. The new ones are made in China. I compared 4 old ones to 4 new ones. In my unscientific opinion, I think the new baits are made with the same butyrate plastic and in the same or similar molds. The plastic feels and looks the same. The clear coat on the new baits does appear to be different from the old baits. The clear coat on the new baits is thicker. This resulted in slightly different dimension between the old and new baits.

The diving depth for all 8 models appeared to be around 7’ on 12 lb. Yozuri Hydrid Line. The actions of the new and old baits seem identical. I fished all baits on the same rod with the same reel. The vibration from bait to bait was the same. I was fishing in 7 feet and just ticking the bottom.

The rattle sound seems similar across all 4 pre-2006 baits. Three of the new bait sounded like the pre-2006 baits. One of the new baits seemed a bit fainter than the old ones. The tone of the rattles in all baits is similar.

Molding ‘dents’

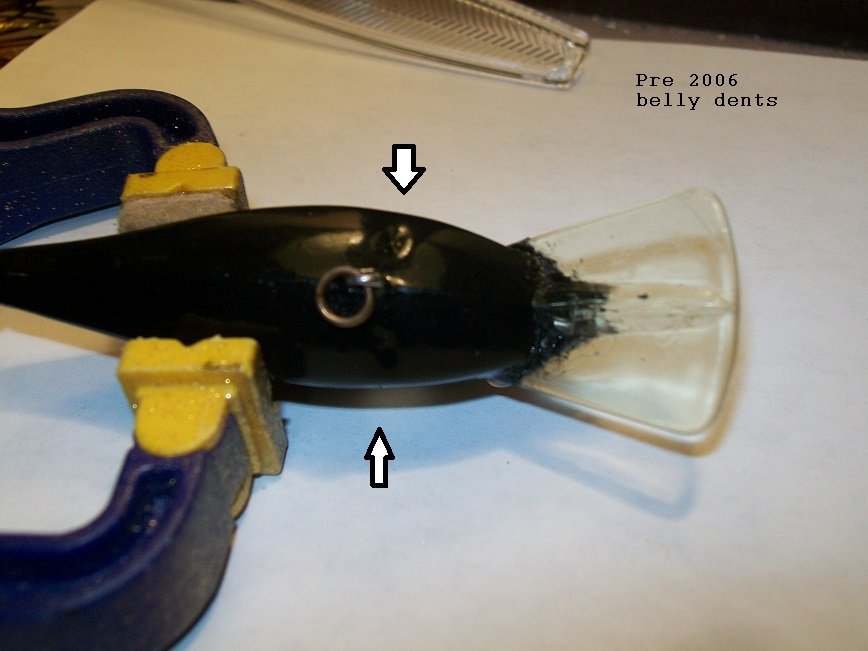

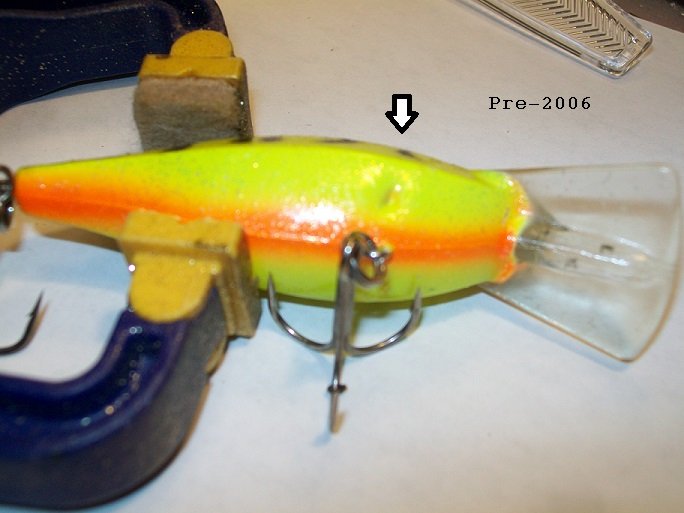

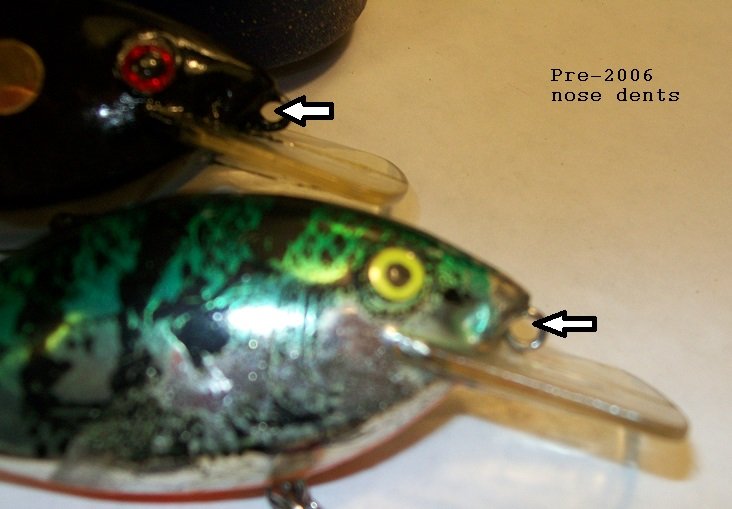

All of the old baits and 2 of the new baits have what appear to be small ‘dents’ where the plastic sagged into the body during the manufacturing process. The dents on the older baits were far more numerous and far more pronounced. Two of the new baits had no dents. One new bait had one very slight dent. The other new bait had two very slight dents.

(Older baits)

Pre-2006 - Black - has two dents on the belly in front of the hook hanger, a dent on the starboard side of the nose, and the starboard side of the tail.

Pre-2006 – Metallic Perch - has two dents on the belly in front of the hanger, dents on the starboard side and port side of the nose, a dent on the starboard side of the tail, and a slight dent on the back near the top on the starboard side. This is the oldest bait in the group which I believe was made in the late 90s.

Pre-2006 – Crystal Mudcraw - has two dents on the belly in front of the hanger, a dent on the starboard side of the nose, and a slight dent on the starboard side of the tail.

Pre-2006 – Bluegill Perch (with orange sharpie on belly) - has one large dent on the starboard side of belly in front of the hanger. This dent is the largest and deepest by far. It looks like and inverted water drop. It also has dents on the starboard side and port side of the nose, a dent on the starboard side of the tail, and a slight dent on the back near the top on the starboard side.

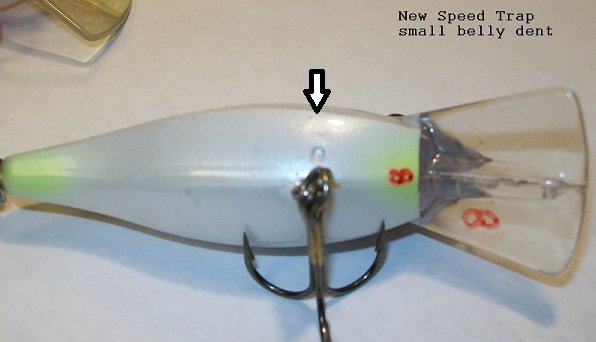

(Newer baits)

Post-2006 – Blue chrome - has no body dents.

Post-2006- Gun Metal Shad – has a very slight dent on the starboard side of the belly in front of the hanger and another very slight dent on the starboard side of the nose.

Post-2006 – Breeding Bluegill - has no body dents.

Post-2006- Mossback Craw – has a very slight dent on the starboard side of the belly.

Because the few dents on the new baits appear in similar spots to where they occurred in the old baits seems to me that they are still made the same. Luhr Jensen must have figured out a way to mold the bodies with far fewer dents/sags.

Clear coat

On the 4 older baits, the clear coat is thin and uniform with no fish eyes. The clear coat on the newer baits is thicker. There are ‘fish eyes’ in the clear coat on two of the new baits so you can see that it is thicker than the old clear coat. Measuring the length and width of the body and thickness of the lip also indicate the clear coat is thicker on the new baits. The thicker clear coat may increase the durability of the new baits compared to the old ones that would not likely survive an errant cast into an object.

This is not a complaint about these baits. I really like the bait. There are usually at least 5 in my tackle bag in different colors. They are very thin walled and were difficult to manufacture. The quality on the new baits has definitely improved. I have fished these baits for 20 years and have caught multiple species on them. The new ones and the old ones both are great fish catchers. The have a very tight wiggle that draws some vicious strikes. They are very stable and don’t blow out even on fast retrieves. The only disappointment I have in the new baits is they discontinued the Metallic Perch color - gold chrome perch pattern with the green chrome on the shoulders and orange on the belly. It doesn’t show well in the pics. It is a deadly bait in the Northeast as it looks like several of the local baitfish.

INCHES Lip **** Pre / Post OUNCE Body Body Port Starboard 2006 Color Weight* Length** Width*** Thickness Thickness pre Black 0.334 2.6135 0.7210 0.0845 0.0845 pre Metallic Perch 0.322 2.6040 0.7185 0.0845 0.0845 pre Crystal Mud Craw 0.328 2.6210 0.7220 0.0840 0.0840 pre Bluegill Perch 0.340 2.6000 0.7205 0.0850 0.0850 AVG 0.331 2.60963 0.72050 0.08450 0.08450 post Blue Chrome 0.330 2.6460 0.7440 0.0970 0.0970 post Gun Metal Shad 0.363 2.6395 0.7450 0.0950 0.0955 post Breeding Bream 0.341 2.6395 0.7465 0.0955 0.0950 post Mossback Craw 0.358 2.6390 0.7445 0.0960 0.0955 AVG 0.348 2.64100 0.74500 0.09588 0.09575 Norman Speed N New Evoo 0.463 2.69800 0.82400 0.07300 0.73000 * Weight with no hardware. ** Length of body of plastic measured from above tail loop to noise point *** Body width just behind belly hanger **** Lip thickness on both sides as close as possible to center hump on the bottom side of the lip Norman Speed N vs. Lurh Jensen Speed Trap

The Speed N is a new lure very similar to the Speed Trap. The Speed N is close in size to the Speed Trap with a similar action. The Speed N is also made of butyrate. The Speed Trap is available in more colors. The Speed Trap also has some bluegill colors and chrome colors which the Speed N does not. Hopefully, Norman will add more colors in the future. The Speed N is made in Guatemala. The Speed Trap is made in China.

The Speed N dove to around 5’ on the same setup that the Speed Trap reached 7’. The Speed N is heavier and casts further than the Speed Trap. The Speed N I purchased had no defects. The Speed N had a tight wiggle very similar to the Speed Trap. They both have a similar lip design. Like the Trap, the N also did not blow out on a fast retrieve. I could feel the action of the Speed Trap a bit more on my rod tip. I guess I would describe the vibration of the Trap as just a bit crisper compared to the N.

The Speed N did have a different rattle from the Trap. The Speed N makes more of a thud knock rattle. The Speed N has 2 chambers that run horizontally across the bottom of the bait that each house 1 fairly large ball. The balls have a limited range of motion, they can move and knock side-to-side. The Speed Trap has one medium ball in a horizontal chamber on the belly with very limited moment that provides a very subtle knock and a smaller ball free roaming in the open body that gives off a fairly high pitch rattle.

I have only fished with the Speed N one time and caught no fish in 40 degree water so I can’t attest to its ability to catch fish. I have had years of success with the Speed Trap. It would be great to have a successful Speed Trap like lure that can hit shallower water. It will be interesting to see how the Speed N does next year. Neither lure performs well being dragged across 6 inches of ice.

Jim

-

2

2

-

3

3

-

Bass Pro/Cabelas has the 1/8 oz Buck-shot for under $8 if you are just looking for a cheaper price. They have that size for 4.99 and 5.49 depending on color.

https://www.basspro.com/shop/en/northland-fishing-tackle-buck-shot-rattle-spoon

The rattle on that spoon looks like the XPS metal worm rattle or Catmaster brass rig rattle. Catmaster is in the UK. I have not seen the Catmaster rattle in the U.S.

https://www.basspro.com/shop/en/bass-pro-shops-xps-metal-worm-rattle

I think it would be cheaper to make your own rattles rather than buying rattles even if you use craft brass tubing. You could check craft and hobby stores for brass tubing. Sometimes the big box hardware stores have it the pull out boxes in the hardware aisle.

I don't have the Buck-Shot spoon. If you have one, you can measure the rattle size and buy tubing of the same diameter.

-

1

1

-

-

I would tape or rubber band some lead to the side of the bait to get it to sit right and try a careful cast or drag along the shore. This way you can test lead in different places before modifying the bait any further. If you are looking at the bait on the retrieve and the right bottom is trying to roll up (a counterclockwise rotation), tape some lead on the bottom half of the right side. I usually attach lead from a 1/8" coil and keep it below the midpoint vertically. My first place to try is usually in front of the front belly hook. I have even used scotch tape applied to a dry bait. It usually gives me a few casts/drags.

If I can find a lead amount and placement that corrects the problem, I will drill a 1/8” hole in the location of the taped lead. I drill up from the bottom between the bottom centerline and outer edge avoiding any internal hardware. You can angle the hole slightly outward if the bait gets wider as you go up being careful not to get too close to the outside edge. Slide the lead into the hole, tape over the hole or use superglue and test again. Once you confirm it's fixed, you can fill, seal and paint the small hole. I have had a dozen or so baits through the years that could only be fixed this way. Something wasn't symmetrical in the carving, ballast, lip or any combination of the 3. I have taken some old dud baits and fixed them with this method. Unfortunately, that was after paint. I figure it's better to have a 1/8" blemish than a non-working bait. If you can't match the paint, paint that spot red for the wounded bait look.

When testing a bait pre-paint, I will seal the bait and hot glue ballast to the bottom for testing. This way I can get the ballast right from the start. I change the lead as necessary and retest. On a large bait, I will use a 1/4" lead coil for ballast.

If you have a bait with too much ballast, you can drill out some lead and fill the hole with craft dowels matching the drill bit.

-

1

1

-

Tying on a crank bait

in Hard Baits

Posted

For bigger baits, musky/pike waters, and saltwater, I have been trying out the Tactical Angler Power clips. For me, they are too bulky to use on a typical bass lure. I have only used them the past couple of years. Easy to change and strong. After extended use, they sometimes can develop a gap like a sprung split ring and need to be replaced. I haven't had any issues yet.

https://www.amazon.com/Tactical-Anglers-Power-Clips-125lb-Bulk/dp/B00CFU18IG/ref=as_li_ss_tl?s=sporting-goods&ie=UTF8&qid=1506089014&sr=1-3&keywords=tactical+anglers+power+clips&linkCode=sl1&tag=jcoutu55-20&linkId=603eed98fccd927b028acbf5a1b8b328

I have not used this type of connector long enough to honestly give on opinion durability and potential failures. But, they are easy to change lures with. It could be a way to go for people with hand issues that make using snaps and tying knots difficult. A few companies are making smaller sizes for typical bass fishing situations. I have not used these smaller ones.

https://www.tacklewarehouse.com/P-Line_Technical_Snap/descpage-TPBB.html

https://www.tacklewarehouse.com/SPRO_Prime_Snap/descpage-SPNSP.html