Ezcorer

TU Member-

Posts

16 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Ezcorer's Achievements

Newbie (1/14)

2

Reputation

-

I kind of did something like it.... I had 2 cup in the microwave of different colors then poured them in my injector, it came out with swirl pattern. but brown and green didn't look real good. with a little practice that would work. wylder

-

I'll be has some also. https://m.uline.com/h5/r/www.uline.com/cls_15_ClearTubes/

-

Looks like it will work! It looks like it will have crazy action win the legs and tail. only one way to find out if it works is to finish it and fish it!

-

Drawing the part takes the longest, anywhere from 1 to 3 hours. then I turn it into a mold, add vents and a spru. that's about 30 minutes. So starting from scratch around 4 hours. then about 4 hours to print it.

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

I downloaded it ladt year and as long as I didn't make $10,000 a year (I wish) with it it was free..... they changed that I guess....

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

Yes! TinkerCAD is great too. it looks like a kids program but it is very powerful. one of the only free programs that you can actually import and modify .STL's. wylder

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

c check out fusion 360 or design spark mechanical, both are available for free (not just a trial download) and real close to solidworks functionality. wylder

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

I am all for using what you have and doing what you can!

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

This is a link for the oogoo mold making. The only thing is don't add the mineral spirits! the mold will shrink a lot once they have evaporated. http://www.instructables.com/id/Make-a-silicone-mold-from-common-household-materia

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

$120! that seems extreme to me. what kind of printer was it done on? are you filling the mold with resin then dumping it out so you have a hollow body? I'm not sure I understand when you said the silicone compresses and you loose wall thickness. would making the walls of your mold help with that?

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

The stuff Mark is talking about is also called OOGOO (you can Google that) but it uses corn starch instead of water. works the same but sets up in about 15 minutes and is the consistency of creamy peanut butter. make small batches it sticks to its self great and you can get aubergine detail with the stuff. wylder

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

Just 10 years ago they were called RAPID PROTOTYPING machines. now they are 3D printers. the cost of the machines has come down so has the cost of the parts that are made. The other thing driving price is what you want your prototype made out of. some of the machines I run at work cost $120,000 so yes the parts I makes are pricey but it is dimensionally acute. If you like to tinker you can get a printer for under $300 and the work fantastic. look around most libraries have printers now. if you can find one and need something PM me I'll get you what you need.

- 28 replies

-

- 1

-

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

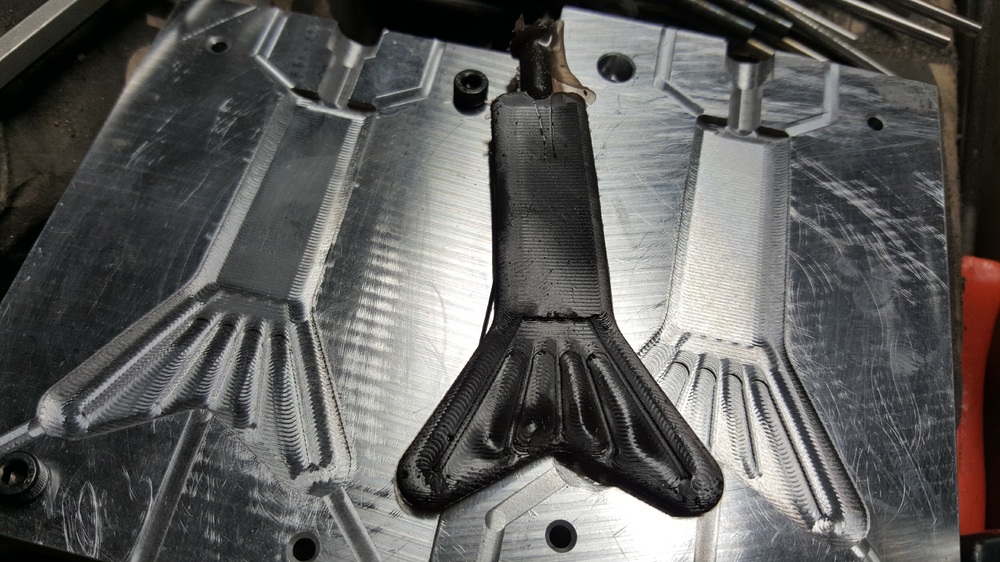

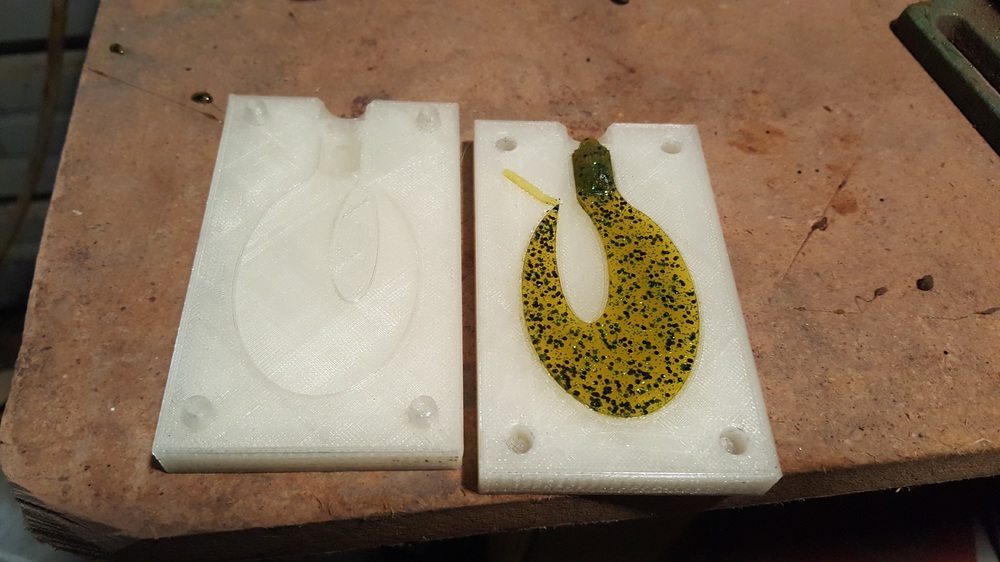

The molds are made out of PLA filament on a Prusa I3 mk2.

- 28 replies

-

- 1

-

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with:

-

howdy yall! I was talking with a guy I work with about a mold I cut on my CNC mill at work. The mold was a tail for a cast swim bait, it turned out great! so I was wondering why not just print on my 3D printer! I did a few quick designs and printed them out. It works GREAT!! you can go from design to water in a day! I have attached a few pics, the aluminum tail mold and then one of a jig body (black mold) and the other (white mold) is a tail i am going to use on a crank bait I'm making. Let me know what yall think!

- 28 replies

-

- 3d

- 3d printed

-

(and 3 more)

Tagged with: