-

Posts

40 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by Jazzatomo

-

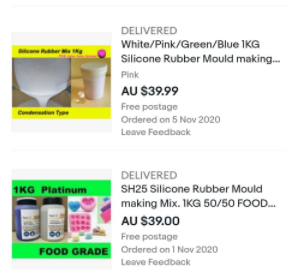

This is what he has sent me. The first doesn't give a type in its description, the second is a 2 part SH25 compound.

-

Will let you know mate. Would have to work out a way to do it in such a way that all the different moulds I have made up. Or just size the smaller ones to an arbitrary dimension. But i can see where you are coming from.... Hopefully in the new year ill have a CNC and i can just do it all in aluminium.

-

G'day all, Asking a question for a mate back here in Australia who is a bit(Massively) technology inept. He has been attempting to make silicone moulds of some soft jerkshads from one of our Australian makers over here. The problem he is running into is that the silicones wont set, or will get distortions and marks along what should be a smooth surface. I have recommended sealing them with nail polish or silicone, but was wanting to reach out and see if anybody has worked out a best solution for the issue. TIA and best regards. Jake

-

I definitely appreciate what your saying Dave. Making masters is definitely a viable option and there a number of approaches from just printing the bait, to printing a half injection mould with the master still in it for each side. Surprisingly, injecting at approx 150 deg C / 302 F produces some great baits, with only the warping of the mould to contend with. Ill get 10 - 15 runs of baits through a PLA + mould before the mould starts to bow and get flashing on the baits. There are higher heat filaments available, but my poor little printer cant get the hot bed hot enough for the halves to adhere correctly. For rapid prototyping I definitely prefer just injecting straight into the plastic. When I can reprint a 6 slot mould overnight, the 2 or 3 days of work to make a pop mould is a bit beyond. Especially when i am testing 1 - 4 moulds a week when I get inspired

-

Been doing it for a few months. I have a basic FDM printer, the ANET A2. I can print moulds and have them inject well with PLA at 0.1mm and 40% fill, but the moulds will warp from the heat over time. Its great for testing ideas, but you do end up with lines from the layers in the final bait. I know some guys who use resin printers, which can print even finer again and they say they get no lines on their baits, but i havent seen the baits close up to be sure.

-

I'm aware, its why I am ordering now instead of when everything runs out Its still a lot stronger than standard plastisol is it not?

-

G'day crew, after going through my initial 6 litres (1 and a half gallons) I bought from here in Australia, I am looking at purchasing the easy stretch from MF, as well as some heat stabiliser to make it a bit more manageable. I am under the impression the easy stretch is as close to a Z-man style plastic, whilst still being a plastisol material. (which is probably still miles off) and also for 1 gallon, would I need 2 oz or 1 quart to get through a gallon of the easy stretch. Thanks again for your help guys, Jake

-

I've made a couple, haven't had any issues of deformation, but I clamp my mould gently between 2 pieces of wood. If you clamped harder the cavity would probably distort or space would appear increasing your chance of flashing.

-

Colormatching - Copper berry - Is this ox blood?

Jazzatomo replied to Jazzatomo's topic in Soft Plastics

shipping to Australia hurts... my last order from MF had 100 USD shipping on it, the order I am looking at placing for 5 gallons of dead on plastisol has $485 USD + for shipping :'( I try and load up in hits to try and spread the value out for when I price my baits out. but in the end its still adds 25% + to the price of every color, scent or glitter I order. -

I think he may mean did you mix it in the bottle before you poured it into your cup. Ive had the issue with bottles that have sat for ages without being rotated. Usually once I take the first cup out, they get back to what they should be for some unknown reason. Have had it happen now with 3 1 liter bottles in a row. Usually i just keep shaking the origional bottle and adding more bit by bit into the dodgy cup until it wants to behave properly

-

Colormatching - Copper berry - Is this ox blood?

Jazzatomo replied to Jazzatomo's topic in Soft Plastics

The confirms it for me. Guess im doing another MF order soon Bugger. Guess I am ordering some oxblood too. That looks awesome! -

Colormatching - Copper berry - Is this ox blood?

Jazzatomo replied to Jazzatomo's topic in Soft Plastics

So to add a bit more information, the first picture isn't a laminate, the colour of the bait changes colour under different light. It sounds like it may be a brown motor oil going off what everyone is saying. At the very least I can give it a go for it. I think that has been made very clear XD -

Bang on. Will try that this arvo!

-

Aint that the truth. The plastisol order I am looking at doing is gonna cost me 3 times more in freight than the product I want to order.

-

Colormatching - Copper berry - Is this ox blood?

Jazzatomo replied to Jazzatomo's topic in Soft Plastics

I can understand why you would say that. It can appear a similar motor oil color in the right light. Its more reddish than the motor oil I have. Ive tried mixing motor oil and strawberry, but it doesn't come close. Here is another picture. -

G'day All, Looking to try and color match one of my favourite plastics. The closest I can find so far I think is Ox Blood, but without already having it in my hands I cant be 100% sure, and the main companies I order from dont have just a straight clear copper. TIA for your help. Regards, Jake

-

The ice water helps them to set up quickly, and helps prevent any malforming if you dont lay it out perfectly on the bench. I do it depending on the number of baits I am running. I always seem to run out of space in the containers I use

-

Im using the medium MF Bags atm and bagging up 10 2.5" worms. If I went bigger the poor baits would be swimming in spare space

-

This was what I was thinking, I would assume the clear plastic would have to be worm proof in order to stop colour leach? The worm oil tip definetly helped. I tried to convince my partner, but she wont take payments in back rubs and good cooking,

-

We didn't end up ordering as a group, but I did place a $400 order with MF, and had no issues with the product getting here. Although admittedly I didn't order any Plastisol. I ended up buying everything Swamp Tackle still had available, which turned out to be a great option, but i am now down to my last bottle of medium and hard plastic, so saving to do an order with Dead-on in the next month or so depending on how many mates want plastics. Thats a great Idea, I tried to do that with MF, but they already had great shipping prices to begin with, so I wasnt stressed.

-

G'day All, After the advice I received here earlier in the year, I have powered on designing my own baits and having a ball. In order to fund a CNC machine to make my own molds or to pay someone to do the machining for me, some good friends have been nice enough to help me get some funds towards it. The struggle I am having is packing the baits neatly in the bags. I want to give them the best product I can from what I am working with, as part of that I want to pack my baits neatly same as what you would find in a store, but am having extreme issues with either my fat hands not fitting in the bag properly, or the baits not wanting to play the game as I try to add them to the bag. Has anybody got any tips that might point me in the right direction? Ill also do a post with a lot of what I have found so far in regards to 3d Printing molds. Jake

-

Now you have me thinking.... . Also, love the pumpkin seed. If you can get a hold of some, try a bit of gold pearl in them to make them really pop

-

Ah yep, I have come across it before. It was going to be the next one I ordered to try, have you used it yet?

-

if your referring to "the fly and lure co" it seems to be invoiced out by u-make-em, so unfortunately they seem to be the same company

-

Cheers mate, I guess that's one advantage of 3d printing my masters is that I can play around a bit easier with #D printing and pop to see how it goes.