Search the Community

Showing results for tags 'weight'.

-

I found this German website that describes hard bait making. I put the page through the Google translation filter and it reads pretty good. I hope it translates okay for you. The interesting part starts near the bottom with step 15. It describes the effect on bait movement for weighting location, bill size/angle/shape and placement, eye loop/line placement and a bunch of other stuff and how it makes a lure dive, wobble, run straight, etc. The translated website is here.

- 2 replies

-

- 1

-

-

- weight

- bait design

-

(and 4 more)

Tagged with:

-

What is the best way to put weight in a crankbait without a lead pot?

-

Hello everyone! When I have built resin baits in the past I have been mostly using Smooth on Feather lite but I have recently started to play more with mixing the ballons into the resin by my self. I am using Alumilite RC-3 and Alumilite Micro ballons. Do you guys have any tip on how to figure out the right amount fast? Resin is exspensive :D! I always seems to mix too much so I need to throw away a lot of resin OR to little. I want the density o the resin to be something like Beech wood, something around 0,70 - 0,80. I also think I prefer to do it by weight and not by volume like everyone seems to do on Youtube wich cant be that accurate? Thanks. /David

- 1 reply

-

- microballons

- plastic

-

(and 3 more)

Tagged with:

-

Hello everybody! Today I made a big misstake at the workshop. I drilled 1 of 2 weight holes in the wrong place on 50 lures today.I dont know how I managed to do that haha! Is there a good way to fill these holes up and then drill new holes in the right position? Maybe by making a filler by mixing epoxy and saw dust? The wood I use has the density around 0,65-0,75m3 and the epoxy I use has the density just over 1,0 so the epoxy is heavier than the wood. /Pickadollbaits

-

I AM LOOKING FOR AN ALUMINUM MOLD TO POUR MY OWN BULLET STYLE WEIGHTS. 1/4 3/8 1/2 3/4OZ SIZES ARE PREFFERED. THE DO-IT BRAND MOLDS DO NOT FIT MY NEEDS AND I CAN NOT GET A RESPONSE FROM SHAWN COLLINS CUSTOMS. ANY IDEAS ON A SUPPLIER?

-

Hey everybody, this is my first post here on TU, and I hope i'm not regurgitating past topics here but... I just cast my first resin glide bait, a 8.5" rainbow trout. My first casting was as a single-piece, but I decided to lay the molds out flat and try it in two pieces. The reason for this was to try and cut weight by hollowing out the front and rear sections when it had cured (which I did), then epoxy everything together. The result is still 7.5 ounces, as pictured. So, my question is: Is it possible to cut this weight of something like this down to, say, 4.5 or 5 ounces? Is there a technique/resin type that can help cut the weight down? I'm using a two-piece silicone mold based upon a hand carved wood trout design I made. Any suggestions would be much appreciated!

-

Hi. First post here. I've wondering about a lip/bill modification that I've seen done on some of the rebel deepwee crawfish crank baits. Megabass particularly adds a bearing into the cylinder under the lip. Has anyone here done something similar with different bills? I was going to give some extremely tough marine style adhesives a try, anyone have any good idea on how this could be done best? Notice the Deep Wee crawfish bill in this picture if you don't understand what I mean. http://i.ytimg.com/vi/vNRkMbbIess/maxresdefault.jpg

-

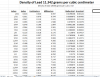

Hello all, There seems to be a lot of questions about how much weight to add to a bait. There are several methods described in other posts dealing with this issue for a “new” bait. I have a system for developing consistency through a line of the same bait as I’m sure many TU members have. My system is in no way perfect but gives me a good starting point. This is my process. I try to build lures by a repeatable process. I also use balsa wood. These two things don’t always agree. Different boards are from different trees and therefore have different densities that will affect the action of the bait and amount of lead that should be added. I have designed a system that allows me to come up with a reasonable starting point for a new lure by deciding how much weight to add. Whenever I try to decide how much lead to add to a bait I start out with math. I take measurements from previously successful baits (weight, vol, density,…) and use equations to get a rough idea of where to start. These calculations in no way are absolute. The different shapes of baits and amount of surface area that is exposed to epoxy or sealant also affect the weight and final volume of the bait. Other factors that influence this include line ties, hook hangers, lips, hooks, split rings….. and the way that many of these are attached to the bait. These equations are meant to be a rough estimate of how much lead to add in the construction. When I first get a board I place it on a kitchen scale and weigh it. I then record the weight on paper and on the board as well. I then use the dimensions of the board and the weight to calculate a density for the piece of lumber using the equation Density=Mass/Volume. (see attached volume table) Using mass values in grams and volume values in centimeters allows me to see what the density of the board is in relation to water (density=1g/cm^3). When I create baits I use a router. This allows me to be as repeatable as possible. I construct a bait by joining two halves together to form a bait with epoxy. I try to be as consistent as possible in the joining of the baits by the amount of epoxy I apply and always press the baits under a set amount of pressure while drying. Once the baits are joined I weigh them on a powder scale to determine their mass. After taking 5-10 measurements I calculate an average mass for the run of baits. By doing so after the baits are epoxied together allows me to be closer on the end product than weighing them beforehand. This negates some of the error encountered in gluing and from half to half. After the average mass is calculated I determine the volume of the lure body by using the known density and mass values. By comparing this volume to previous baits I can get a rough idea of how much weight should be added to a bait. (see area of drill bit table, multiply by depth of cavity and gr per cubic centimeter for a rough estimate of mold size needed) I then take the amount of weight calculated and install it and finish a lure with all the necessary components and coatings and test it. Sometimes I don’t coat the lure for the sake of speed. From the test I make adjustments accordingly on the amount of weight needed, hook size, line tie position, bill angle…… Once all this has been done for a particular style of bait you can adjust the amount of weight needed by recalculation of the density. Then you can adjust the weight accordingly to the density of a new board to get the same rate of rise in the lure. The action will be somewhat different as the distribution of mass in the lure is slightly different but usually the difference is negligible. By always recording all the measurements and calculations it is possible to get very close to a run of baits from the past that have turned out to be very successful. This can then be followed as a recipe. I’m sure this is nothing new but thought some of the members might benefit from an explanation of what it is to be repeatable and how to do so. The process, once again, in no way is perfect (bits have different points, walkout,....). It is a good reference and starting point for me however. Good Luck, CarverGLX

- 16 replies

-

- 1

-