Search the Community

Showing results for tags 'plastisol'.

-

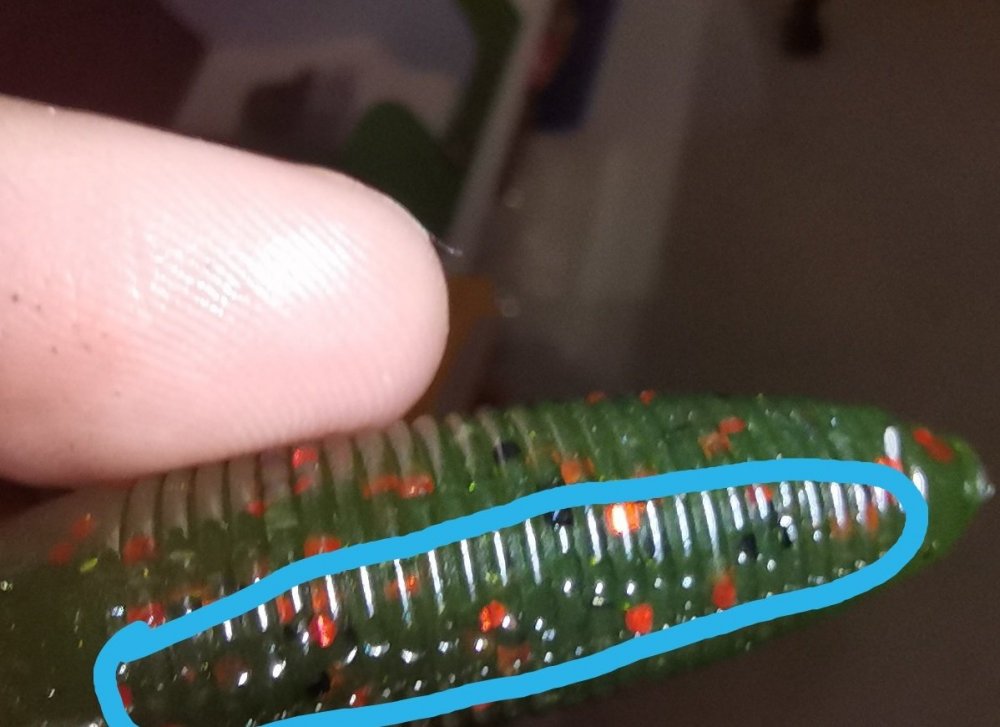

Hello all, I need help with my baits done in a aluminum custom mold. The mold has 6 cavities and all the baits when they are injected have air bubbles in the rib. I've tried everything but I can't get rid of these bubbles. I use a vacuum pump, suck up the plastic and then turn the injector upright to eject a small amount,etc etc. Can someone help me? Thanks

-

I just scored a riteheat. Im new to soft plastics. Any advice or recommendations on using the thing would be great.

-

Is there such a thing as a conversion weight from the time Plastisol is room temp liquid, never used till the final soft plastic product? i.e. a gallons weight= X cured Baits= Y Is X and Y the same or conversion? Obviously hardner, and other products added will change the weight but straight product is the terms I speak of.

-

I’ve been doing research on making my own soft plastics and can’t seem to find if I need softener or not. I haven’t ordered anything yet so is there anything else I need besides plastisol, bait color, and maybe scents or glitter? If you would like to help me and just tell me if I need it or not and the ratios it would be greatly appreciated.

- 9 replies

-

- plastisol

- soft plastics

-

(and 4 more)

Tagged with:

-

Hello. Has anyone ever used lurecraft 576 soft formula ECONO plastic? If so, how does it perform for small hand pours versus the super soft " western " formula. Also wondering if it still floats or not. Its cheaper than the one I've been using . Thanks

-

-

Not sure if anyone's seen it, but Dead On Plastix has the new site up. I've been using the swim/jerkbait formula for the past 5 months. It is without question, the best plastisol I've used in my 16 year's of soft bait making. Crystal clear, won't scorch, WAY CHEAPER... It's awesome. Thought you fellas might appreciate the head's up. www.deadonplastixllc.com

-

Hey community, This week's formula will be a plastisol, I would recommend this recipe for light fresh water fishing, and less rugged underwater terrain. I would say to use dye normally on this recipe since it contains a dye solvent factor now as paraffin oil coating with fish oil. Please feel free to ask questions or point out typos. #5SMs stands for 5th numerical recipe, S for soft/not so durable, M - medium weight. -64% DINP Plastecizer -13% Emulsion PVC paste resin -2% Soybean oil epoxy -2% Paraffin oil with fish oil 1 to 1 ratio -2% Urea -5% Organtin stabalizer (tetramethyltin) -6% Nauguard -6% 6705 Plastic Softener (http://www.lurepartsonline.com/Online-Store/Plastic-and-Additives/Plastic-Softener.html) Thank you for reading this formula.

-

This formula was designed to be extra heavy for far casting or deep water fishing, without the use of salt or glass(I will do some with these in the future), It uses tungsten-iron-silica powder (aka black sand), i would recommend this recipe for anyone with a ball mill( as the powder must be fine). When handling this material please wear a face mask, goggles, and remove any nearby magnets. Please work out side if possible, when it is not windy. Formula 3DH or 3-third D-Durable H-Heavy. Keep in mind that this formula is theoretical, reason is I don't know what you may be working with as far as equipment. Percentage of Materials -67% DINP Plastecizer -15% Emulsion PVC Paste Resin -2% Soybean oil or Mineral oil (90% pure mineral oil) -3% Tin Thermal Stabaliser (Tetramethyltin) -5% Dispersent (website on dispersents https://www.byk.com/en/additives/applications/plastics-industry/pvc-plastisols.php I do not work for any of the companies mentioned in this website) -8% Black Sand .1 microns to .75 microns

- 10 replies

-

- plastisol recipes

- plastisol

-

(and 2 more)

Tagged with:

-

This is not a new formula, but does contain different additives for many different applications, (including for flexible plastisols or polysols). Here have the link - http://www.hanserpublications.com/SampleChapters/9781569905432_9781569905449 PVC Additives Schiller SAMPLE PAGES.pdf Also I will be placing New Formulas every Friday, Mostly plastisols, then polysols or organasols, i will try to go by votes it at the end of the next formula to see what the community wants me to formulate next, but if i am unable to to formulate it i will do another i am able to formulate (if you any questions feel free to ask). Please comment for the next formula today and tomorrow.Thank you for reading this post.

-

New Medium weight formula with a PVC base. But reminders that this formula theoretical and might not work as intended since I myself haven't tested it, but if you do experiment with it feel free to share or publish it no credit to me is necessary. I would recommend it for middle-deep fishing, it is compatible with translucent dyes. #2SM stands for Second (Numerical), Soft Plastic, Medium (weight) Formula -70% DINP Plastecizer -17% Emulsion PVC Paste -2% Soy Bean Oil -5% Thermostabalizer -5% Dispersent Agent

-

Any suggestions on how to reinforce ribbontail worms to make them "tougher" yet still remain flexible.

-

Hey everyone just wanted to see if anyone new what kind of plastisol or brand of plastisol big hammer swimbaits uses for thier plastic I realy like the feel of them. Thanks

-

Hey guys, I figured this would be the perfect place for me to reach out to you guys who make soft plastic baits. I am a senior Industrial Design student at Wentworth Institute of Technology in Boston, MA conducting research for my senior thesis project. My goal is to research the methods of the at-home (soft plastic) lure maker in an attempt to make the process safer and more efficient in the home workspace. Aside from being a student, I am also the product designer for Optimum Baits and a freelance designer for several other lure companies. While I do have a prototyping space of my own, all of the actual production of the designs are carried out at a large scale. This does not provide me with much insight for my project. From what I have seen in this group, there are some extremely gifted and creative people in here. Any of your input would be greatly appreciated! Thank you for your time. https://goo.gl/forms/y7DImLhsLPS4pqgV2

- 6 replies

-

- soft plastics

- plastisol

- (and 5 more)

-

I have now completed my Soft Plastic delivery system in 3 styles all concepts and drawings at this point. Thanks for all the help. I'm trying to assemble a working system with parts bait makers have and stuff that can be purchased to keep the cost down. I believe I have a solid idea now. The only thing that I'm not sure of yet is, Does Plastisol, when heated to the proper temperature, pour into a aluminum mold (not injected) right down the center of the hole and fill the cavity to make a bait correctly ? This is one of my 3 designs if it works.

-

To control Temperature for Plastisol the best thing to do is get a PID Temperature Controller. One can control the temperature see examples of units in links. One needs to know what voltage, amps and temperature range their working with. Some of the suppliers we all buy our Plastisol supplies from that are making injection equipment or heating pots use PID controllers. Some PID's come as kits some you buy SSR and Temp probe separate. I can control Lyman and Lee melting Pots with Plastisol with Automatic Stirrers. Does anyone else use a PID (Temperature Controller) ? I am also looking for some sort of POT/Canister about the size of a Lyman or Lees melting POT, either Cast Iron, Aluminum etc .... to make a smaller injection machine. I don't want the heater and the dispenser that the Lees pot has in it, I just want a container. I will then add a PID controller a Band Clamp heater, a automatic stirrer and some other items for injecting. At this time a Presto pot system is too large I want to make a smaller system anyone have any ideas of a pot ? MYPIN TA4 and Auberins are popular to use. http://www.auberins....o&products_id=3 https://www.amazon.c...ypin ta4 "ssr" http://www.ebay.com/...r-/301365612354

- 15 replies

-

- 1

-

-

- pid

- temperature

-

(and 3 more)

Tagged with:

-

Hey all, I have a problem. No, it's not finding enough time to make more baits, we ALL have that problem. What I am having a hard time doing is making a cup of crystal clear, bubble free plastisol, which I can then shoot into a 2 cavity mold, and, if it doesn't turn amber (BIG if), then a cup allows me 5 shots = 10 baits. Currently, I am lucky to get 3-4 shots before it changes color, and that is if I can get a clear cup of bubble free plastic. I currently have a microwave and a hot plate, the microwave is fast, heats up the material quickly, and creates foamy cups of plastic that just **** me off. The hotplate does a better job if I go low and slow and stir very frequently, but as often as not it will just go amber even before it reaches 350 (using a digital heat gun), like it's getting too much heat. Heat stabilizer or no stabilizer, it doesn't make a difference, with either the micro or hotplate. I do not want to start a plastic war, I won't even say which brand I'm using, other than it's a reputable brand which sells lots of plastisol, it's the saltwater formula (hard), and it works great if I put any colorant or glitter into it, I can shoot baits all day so long as they are colored, one of the best patterns is black with red eyes, easy-peasy, but one of the patterns that works so well is a clear bait with a little color along the back (It's a sandeel bait). I'd guess that 2 out of 20 that I'm making will be acceptable, meaning, it pleases me.....no bubbles, clear plastic, and even though the fish don't seem to care, I do. If I'm going to spend my time doing something, I want it to come out the way I want it to. So, if anyone has a recipe for a cup of clear, bubble free, non-amber plastic, I'd love to hear it, or see it, post a pick in the image forum. I'll post a pic of one of my baits in there so you can get the idea. I have also done a lot of reading here using the search function, and have mostly just read a bunch of bitching about plastic. Can we please avoid that? But if you have a specific brand which has allowed you to get really clear plastic, I'd love to hear it. Thanks, Ed

-

Hey guys so recently i have been looking at both types of Doit-Molds Plastisol. Ive read both descriptions and they dont seem to have many differences. Which one do you all prefer? Im assuming the Crystal Clear is going to be better?