The Plastics Man

TU Member-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by The Plastics Man

-

True. However, as most stirrers may not scrape from the surface of the pot as there's usually a millimetre or so gap , if there is a hot spot, it could scorch. I found that my pots , after years of use have evidence of hot zones and if I do not work that particular spot when reaching temp, it does scorch and results with burnt flaky bits. It's a double edge sword IMO I am thinking of spending $ on a set of larger presto pots and converting with PID's with taps to drain out a quart at a time. But ultimately , I would love to have a heat exchanger unit/ pump designed to constantly feed my hotrunner machine or have an heat exchange/ injection unit designed for a series of multi cav hobby molds and move away from the hotrunner and microwaves all together

-

Great Information. I am thinking with the element, as most electric pots have "hot spots" around certain areas on the element ring, each pot will have different characteristics, finding that and placing the T coupler as close as possible to the hottest spot ? Just a thought

-

I must have got him during a bad year. Took over 12 months from build to delivery. You got express service I see. I hear and agree with your warnings.

-

If and once you do have your machine built, replace all o rings with nitrile buna rings and the quick clip air connecters with quality 90 degree swivel connectors . The silicone O rings used just don't cut the mustard and the air line clips are a design flaw on the lids Apart from these flaws and the time and woeful excuses , they are a solid machine

-

Carmens soft plastic supplies will have bait plastics in a month or so, Browndog's custom tackle also has BP which is of industry standard. why waste your money on no name rubbish from TS? Unless you wish to fund his meth addiction. All you guys have talked about no chemical company in Australia that makes lure grade plastisol which is correct. Yet TS claims his "pretty good" plastisol is wholly Australian made ? Makes one wonder

-

Jim Message sent

-

If you want it transparent , add your base colour/s to your raw plastisol. To make it opaque , add white to your cooked plastisol. this will lighten up your pumpkinseed colour so make sure to adjust. Here's my take in this colour

-

Try Lurecraft Caramel If you want a darker berkley pumpkinseed, LC caramel , LC Natural to darken

-

Jacob's Baits Deluxe( pro) Injection Press

The Plastics Man replied to The Plastics Man's topic in Soft Plastics

Well done .... I've been trying to find the website to this company. any links ? I have also noticed an update over at Jacobs where he is trying to catch up on back orders so it looks like he's back on track with production. Another email sent to secure a purchase. Hope he responds this time round -

Jacob's Baits Deluxe( pro) Injection Press

The Plastics Man replied to The Plastics Man's topic in Soft Plastics

Yes , from what I gather, the blending block with the Hotrunner model would have to be disassembled for the runner to be removed between shooting cycles Just another un wanted process to slow you down. Main question still unanswered. At least a reply for Rick with confirmation if they will be available and when. -

Has anyone heard or know of when Rick will be putting these back into production? Unable to place order via website. Have sent a couple of emails to Rick with no reply. Not wanting the other brand version with detachable but required blending block Ready, willing and waiting to depart with $$$ once available.

-

I have used my unit roughly 4 times since receiving it a few months back... still nutting out the PID's and actual plastisol temps. to me the plastisol temps are way higher than what the temp probes are sending. Some molds prefer a lower temp to shoot laminates correctly whereas others are happy only at higher temps. Like said , still working out methods. When requiring perfect shots ( small production work) I've resorted back to the Basstackle dual injector and open pots for minimal wastage and time. Once workloads drop I may have time to re melt sprues and crud plastic to fully nut out the system and maximise it's potential Definitely not a plug and play unit .... but what is ?

-

Thanks for the reply :-) It was a couple of weeks ago, but good news. There was a reply in my inbox this morning with all the required info about the units, Just waiting to find out how long of a lead time to have one built and shipped.

-

Anyone here on this great forum who has direct contact with Ultramolds ? I have sent a contact us form and a direct email to them with no reply. Seeking further info on potential purchase of their Shooting Star System. Cheers

-

Thinking about getting back into pouring worms

The Plastics Man replied to bernerbass99's topic in Soft Plastics

Spot on there Mark. With a pre mixed Colored 55 Gal of plastic, enough volume to shoot a production mold, being cooked per shot, there's no over heating, repetitive re melting etc, etc. = consistency Even using a Jacobs press, and at a lower temp, lighter colors do yellow up a little ( not by much, but noticeable) as the quart runs down after several shoots. Thinking of adding an auto mixer just to keep the mix churning. Memory issue is how you store the final product while curing and how you either bag the product or store them. Plastisol is the main material used by all, just a plethora of brands and grades, then you have your custom in house blends. -

It's a pity that the port ( Nozzle) orientation cannot be changed. With the two posts and the nozzle being off set to the two chambers , it will not allow enough space for shooting laminates with certain molds. Jacobs do produce great consumer based machines. emailed Rick to see if the pro machine can be custom built to accommodate the correct orientation for my molds. unfortunately not :-(

-

Quick question regarding the available scents on offer for soft bait makers. Is it sold as an extract providing the scent only or is it much like the refined oil which can be bought and consumed as a fish oil protein/ amino fatty acid supplement. I do not add any scent/ oils to my finished products but do add scent in the final stage of cooking my plastisol just before pouring. You hear of Amino infused soft baits. Just wondering if I'm on the right line of thought.

-

What temps are you cooking at ? Never used the brand but, I've always cooked till the consistency was enough to shoot. Finally introduced an infra red thermometer to the process. I was way off ( Below). Now my curing time has been reduced by a week. Virtually a dry bait once cooled off.

-

I know Clearbags.com can supply printed bags, This is where I buy my unprinted bags from. In saying this, they may have them manufactured and printed by third party offshore though. I've been looking at getting my printed bag supplies from china. Looked into it and ATM procrastinating about it

-

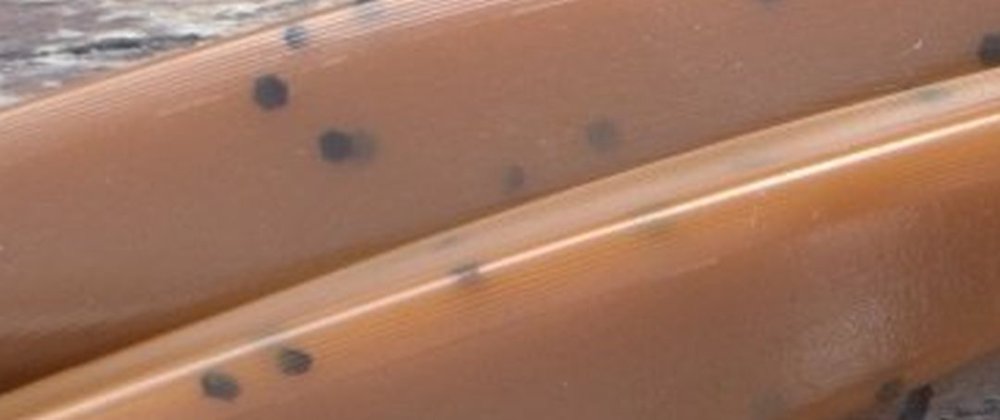

Cheers Frank. As long as it doesn't affect the original intending colour ( unless it is placed under a black light). I do have a lot of clearer transparent colours in my range which I would not want to lose however, wanting to enhance them through using a UV liquid. The attached pic is black naturally and the same under the black light I have sent off a contact us form to Lureworks and wait for their response

-

I'm getting specks through the finished product after, adding to virgin plastisol. Thought of doing the unthinkable and whisking the plastisol with a mixer on the drill, then heating a little then whisking again before it reached 100c Degree The specks may be a good thing, Who knows how a fish thinks and how aquatic life exhibits their colouring attributes I only have the green UV powder but I'm looking for some blues and a red if available The UV glo 130 seems to be an opaque colour which will be the dominating colour I guess. I'll send a message to LureWorks to confirm Thanks for the replies

-

Thank you DaveMc1

-

Thanks Frank. I did go to the website and found the Dip & Glo range. Not sure if it's obscure in the site or not but I'm looking for an additive to mix into virgin plastisol rather than just dipping the made lure into the bottle. I'm finding the UV reactant powder I have is not dissolving completely and was advised some time ago about going the liquid method.