BTL

TU Member-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by BTL

-

I wanted to do the same thing. Didn't want to have something custom machined, so I tried to make my own mold out of Vac Master 50. Went over the instructions and watched the videos over and over, but it just did not work for me at all. I used an absurd amount of mold release too. Tried making two different molds and both were a disaster. I will never bother with it again. I don't know what kind of plastic you're using, but the medium plastisol I got from Alumilite was the same way. It could just be that you're not stirring it enough though. If you want to be original and also produce real quantity, it's probably just best to bite the bullet and get a custom mold. Or better yet, just do what Apdriver said.

-

I started using KBS because people talked about how simple it was. Just dip and hang! But there's nothing simple about it. KBS requires so many different accessories and so much babying just to use it at all. Need to transfer to a new container with a seal on the lid, use bloxygen, thin it with xylene, paint must be fully cured and precoated with floor gloss before use, it smells godawful, takes several days to dry, gets bubbles, and requires multiple coats for any kind of durability. Oh and be sure you don't leave the lid 1/8 turn too loose or the whole jar is ruined. So glad I got away from that stuff. It might be good for cars but it has no place in lure making IMO.

-

That's interesting. I may have to try that. I believe it was messy, the slightest breeze will send that stuff everywhere.

-

RE: microballon ratios. One unfortunate quirk of resin I've found is that it behaves completely different based on temperature and humidity. I thought I had found my perfect ratio of weight:microballoons and then when summer came around I started getting massive bubbling and swelling from the humidity. To the point that lures which used to sink fast would float like a cork. This has only been an issue for me with polyurethane resins like RC3 and Alumilite white. The clear resins seem to be unaffected, which fortunately is primarily what I use. They come with their own issues though, like long cure times and the need for vacuum degassing.

-

After trying UV resin last fall, I can't imagine I'll ever use anything else again. Dip, hang, fishable lure in under 5 minutes. Smooth and rock hard. The cheap stuff on Amazon works great.

-

Did you have to send in a CAD file to have these baits printed, or did you just describe what you wanted? Been thinking of doing the same thing. I make resin lures but I want some new masters to make molds with.

-

Make sure you put your lures as close to the lights as possible. Less than an inch if you can.

-

Could you use a split ring for the connection? I make soft plastic twitchbaits with harnesses. Trying to make them with internal flotation too and it's an absolute bear. Everything that floats either bubbles or melts when you submerge it in hot plastic.

-

Thanks for the review. I'm itching to try this stuff.

-

Baitplastics has a new formula called Flex 200. That's probably the one. Anyone tried it yet?

-

I am in Virginia, a fairly high humidity area. This wasn't a problem at all during the winter and early Spring though. At first I thought it may be because I was using the last remnants from an older batch of resin, but then I opened up a new package and had the exact same foamy results with the new stuff. So I think it has to be humidity rather than moisture in the bottles. I have some white too, I may try that next to see if it behaves any differently.

-

The last few times I went to pour baits (Alumilite RC3) I noticed the resin was expanding in the mold, and afterward when I dropped the baits in the water, they floated, instead of sinking like they used to. From what I've read, this is foaming due to humidity. I'm pouring indoors but I guess it's still a factor. I spent months getting my ballast and microballoon ratio exactly where I wanted it for a steady sink with a nice wobble. Now it looks like I have to start over again and change the formula based on the time of year. This is making me want to get away from resin altogether. Is this right, or is there a way to achieve consistent results without constantly tinkering and wasting material based on ambient humidity?

-

I'm glad it's not just me. DOP gets rave reviews from most people and sells out as quickly as they stock up. It's nothing but air and yellow plastic for me. Not even sure what to do with it. I don't understand what the difference is between experiences, I know not everyone is degassing it. I really want to try some MF, but the price does kinda scare me off. Very intrigued by easy stretch.

-

If I need a vacuum chamber just to use Dead On, I think I'm gonna stick with Baitplastics. It's much clearer too, not to mention less expensive.

-

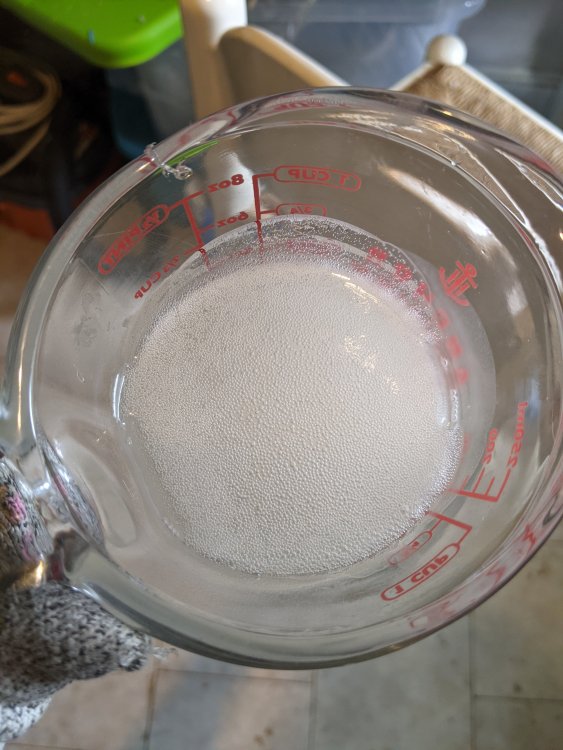

So I just got my first gallon of Dead On, and I don't have any problem with viscosity, but the bubbles are intense. There is more air than plastic. I'm using black label saltwater and stirring with a stainless steel butter knife in a pyrex cup, using a microwave. The pic is after 60 seconds in the microwave before I've even stirred it, it only gets worse after I do. The bubbles aren't just on top, they're suspended throughout the plastisol. It's also very vecloudy, which may be due to the bubbles? It sets up fine but the appearance is awful. Prior to this I was using baitplastics and never saw anything like this.

-

I'm dying to try Easy Stretch, just putting it off because of shipping $$. Would you say ES is as durable as saltwater plastic? How about clarity?

-

I'm glad you mentioned the injection runner, that was another dimension I wasn't sure of. I think my bait is about .70 at it's widest point, so I guess I may want to widen out the runner below the port. Yeah it will eat up a lot of plastic, but it's worth it if the results are better.

-

Great reply, thanks. I was planning for a 4-cavity mold. The baits will be single color, I paint them afterwards. I didn't think about the wire cooling the plastic, that's interesting. Maybe that's part of why my hand poured baits have been inconsistent. Sounds like I should probably go for somewhere between the line tie and the belly hook hanger since that's the thickest point. Maybe a small vent on the back near the tail.

-

Hi guys, new here. Been reading like crazy for weeks and finally joined, what a wealth of information this forum is. Anyway, I'm tired of inconsistent hand poured baits so I'm planning to make a 4-cavity injection mold for a wire-thru soft plastic bait I've been working on. I don't have a picture on hand, but the bait is similar in size and shape to a Rapala Subwalk, just made of soft plastic. The line tie and hook hangers are in the same locations. This will be my first injection mold and I'm not sure where to locate the sprues and vents on this bait. My first thought was to put the sprue on the chin just below the line tie. Another idea was to just make the sprue straight out the tail, meaning I'd be injecting right over the rear hook hanger, and just trimming off the plastic after I'm done. I'd like to place it so it's both inconspicuous and also fills efficiently. Im also not sure if there's a strategically advantageous location for vent hole(s), or if a vent can go anywhere. I'd appreciate any suggestions for locating the sprue and vents!