-

Posts

7,438 -

Joined

-

Last visited

-

Days Won

238

Content Type

Profiles

Articles

TU Classifieds

Glossary

Website Links

Forums

Gallery

Store

Everything posted by Vodkaman

-

I have had problems in the past when my 'cookies' and history were over filled, even though other web sites were working perfectly. Do a Google search on 'how to'. I did mine a few weeks ago. After clearing, log out and restart computer. Dave

-

I am not aware of a first post delay, but it would not surprise me. The site has been plagued for several months with multiple spam from China. You should give it a day or so and try again, if that fails, report back here and I or someone will help you. Dave

-

As Aulrich points out, tow eye location is very important, and should be a part of your experimentation. Dave

-

In my early days, I looked hard for a formula for lip length and width, it was the engineer in me. But alas, I failed. A sharp edge on the front face gives a stronger action, not so sure it is enough for you to notice. The thing is that every feature affects lip length; length and width of back, position and angle of lip, position of COG, and any other feature that I fail to mention. I make the lip a tad too big and trim it back until I get what I am looking for. Dave

-

I abandoned this as a bad idea. Dave

- 16 replies

-

- 3d printing

- rod building

-

(and 1 more)

Tagged with:

-

I don't understand their strategy as all it does is annoy people. No one is going to visit their site.

-

Soda - I believe the problem here is that some people are quoting you numbers by volume rather than weight. The highest percentage MBs I managed was 30% by weight, and I achieved this by injecting the mix using an icing syringe (as in cake making). The consistency was that of English mustard and definitely not pourable. For normal pouring, 12% by weight sounds about right for a maximum. Dave

-

Lots of PM discussions. Really nice guy, knowledgeable too. RIP Dave

-

Perhaps a through bolt and a wing nut to increase the clamping force. Dave

-

I found the Uncle Jim's video. It shouldn't be difficult to knock up a similar jig. The problem is coming up with something to use at the waters edge. Something that attaches to your thigh, maybe velcro. I am probably over thinking the problem as usual Dave

-

I think this is a case were a photograph is justified. A picture will provide a lot of information. To make a judgement give length and weight of lure. How does it float. What body material, weight and position of ballast weight. You should not be wasting time and effort painting a new lure until you have proven the design works. Dave

-

Very sorry to hear this news Kurt. I wish you well Dave

-

Good read. I am very close with the 'violent action' lure. It was something I stumbled across by accident back in 2006 but I was never able to reproduce it. Now I have figured out the fluid dynamics of what I witnessed all those years ago, i Just need a 3D printer to test the hypothesis. Along with the violent erratic action, with a minor tweak or two, a very exaggerated hunting action should be possible. I need to make more of an effort to get the printer and start testing. Dave

-

I was hoping you would use weight, using volume, as some people do, is meaningless. This has been a good subject, I have followed with great interest. But, you should have started a new thread for it. Do NOT do it now, way too late, just a note for next time. Dave

-

My plan would be an external turner, operating 24/7. After the initial manual mixing, the plastisol would always be available. I haven't figured it out yet. I am thinking about the Falkirk Wheel boat lift as my inspiration. I know, jugs of plastic are a lot heavier than lures on a turner, but I am thinking the same motor power for the drive. You can have a laugh now Dave

-

Using 3D printing to make soft plastic fishing lures (My Way)

Vodkaman replied to TCBtacklebox's topic in Soft Plastics

My suggestion would be to design in 'bolt on' backing plates with recessed bolt heads. This will help keep the shape of the mold halves, and simplify assembly with permanently fixed backing plates. Make the printed halves identical, so you can print extra halves if problems arise. I have to make more of an effort to source a 3D printer here in Indonesia. I have been lazy. I will be printing hard-baits rather than molding. This gives me the opportunity to improve the shape beyond 'mold-able', and with the added benefit of making my printed lures difficult to copy. Dave- 14 replies

-

- 1

-

-

- 3d printed

- 3d printing

-

(and 1 more)

Tagged with:

-

Very interesting explanation and novel technique. Nothing wrong with the English. Dave

-

I was hoping the 'over-fill' method would work, so thanks for confirming that, as the weighing the correct amount would get very tedious in a hurry. I look forward to some pics of your methods. Dave

-

This is interesting stuff, I am tempted to buy a kilo just to keep around for any future projects. There are a few problems with our application: 1 - It is too thick to pour or inject, so that means weighing an exact amount and pressing into the mold halves and closing, avoiding any bubbles or voids. 2 - The density of 1.145g/ml makes it heavier than water, so a hollow center has to be included in the mold. This means molding two halves separately. 3 - Too slow for production, but fine for own use. A 3D printed mold might work well, the flexibility will help assembling the two halves. My post reads a bit negative, but this could be fun to work with. Problems can be solved. Dave

-

A mistake that I made in the early days of lure building, was testing without hooks fitted. The addition of hooks in weight and fluid effects changes the action of the lure, sometimes sending the lure outside the design idea, or at least disappointing after the initial hookless trials. So my contribution is; Always fit the hooks for testing. Dave

-

Yes agreed. Function not form I am sure would have been my advice, especially in the early stages of a project. Dave

-

Strange that this is the only color blending issue that you have. There are other blends that could potentially cause problems such as yellow and red. I am sure there will be a simple solution, perhaps a mist of clear can spray, or even hair spray. Just thinking aloud Dave

-

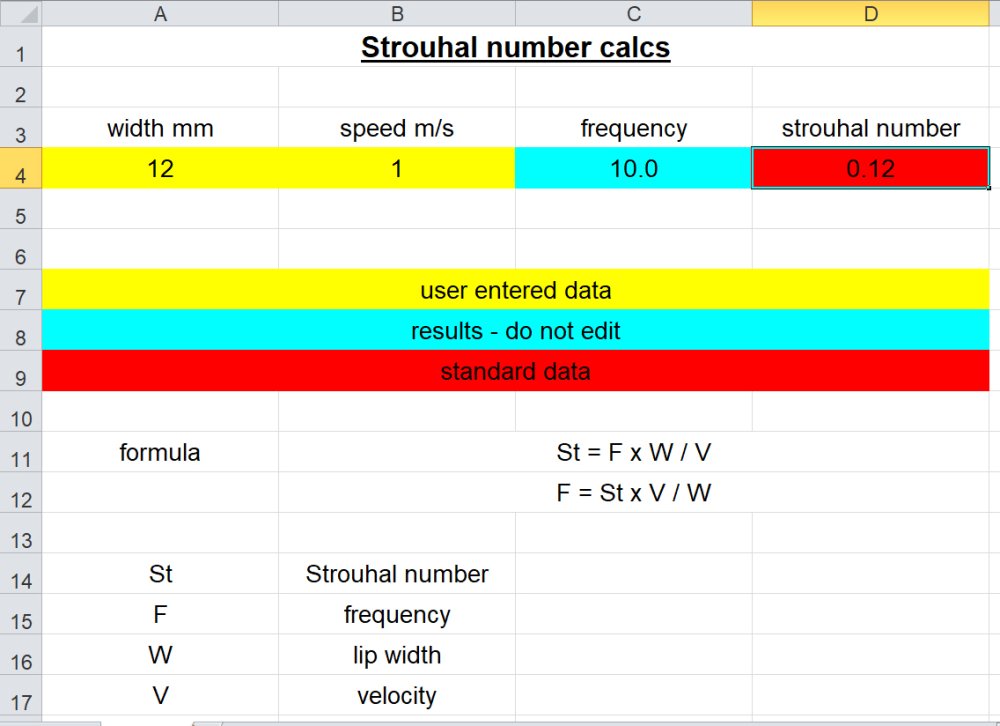

You should at least take a look, it is very simple. Here is a photo of the screen. simply enter the data in the two yellow boxes and see the result in the blue. The rest is information about the formula which you can ignore. The red box is the Strouhal number which you can change to see the effect. Dave

-

There is a formula for the frequency of the wobble, called the Strouhal formula. It sounds complex but it is very simple, only requiring a simple calculator. F = St x V / W F = frequency of the wobble. Cycles per second. St = Strouhal number, about 0.12 for flat lips. V = velocity, how fast the retrieval, measured in metres per second. W = lip width, measured in metres. have a spreadsheet that eliminates the fuss, just type in your data. Computers only. Just message me. Dave