Leaderboard

-

in all areas

- All areas

- Images

- Image Comments

- Image Reviews

- Albums

- Album Comments

- Album Reviews

- Topics

- Posts

- Stories

- Story Comments

- Story Reviews

- Classified Ads

- Classified Ad Comments

- Classified Ad Reviews

- Records

- Record Comments

- Record Reviews

- Websites

- Website Comments

- Website Reviews

- Status Updates

- Status Replies

-

Custom Date

-

All time

February 2 2011 - May 13 2024

-

Year

May 13 2023 - May 13 2024

-

Month

April 13 2024 - May 13 2024

-

Week

May 6 2024 - May 13 2024

-

Today

May 13 2024

-

Custom Date

11/12/2020 - 11/12/2020

-

All time

Popular Content

Showing content with the highest reputation on 11/12/2020 in all areas

-

I definitely appreciate what your saying Dave. Making masters is definitely a viable option and there a number of approaches from just printing the bait, to printing a half injection mould with the master still in it for each side. Surprisingly, injecting at approx 150 deg C / 302 F produces some great baits, with only the warping of the mould to contend with. Ill get 10 - 15 runs of baits through a PLA + mould before the mould starts to bow and get flashing on the baits. There are higher heat filaments available, but my poor little printer cant get the hot bed hot enough for the halves to adhere correctly. For rapid prototyping I definitely prefer just injecting straight into the plastic. When I can reprint a 6 slot mould overnight, the 2 or 3 days of work to make a pop mould is a bit beyond. Especially when i am testing 1 - 4 moulds a week when I get inspired2 points

-

I have the lurecraft & it doesn't take much to do you because it is pretty strong stuff.2 points

-

As I do not build gliders or jerk baits, all that I can do is throw a lot of theory out there, to help you understand how the lure works. Understanding the theory helps the builder to design a lure to take advantage of the forces accordingly. Of course, experienced glider builders will have already figured this stuff out even if they do not know the reasons why their lures work. Experience is a valuable tool, theory only gives you a ‘leg up’ at the start. As you have already figured out, this is a very complex issue with multiple factors to be taken in to consideration. The apparent ideal solution for a lure to swim a long distance with efficiency is an arrow with all the weight at the front. But we already know that this would not work in water as it does in air because of the nose down attitude, like I said; multiple factors. Also, the super aerodynamic shape of an arrow is designed NOT to produce vortices. When we fire an arrow in air for maximum distance, we apply great force and we aim up at 45°, and due to air resistance, the arrow falls at 70°+. Target sports for darts and archery only use the top of the flight arc. Also the arrow is designed not to swing from side to side, a definite requirement of the lure. As for the lure; we want it to travel in a straight line as far as possible, then on the next pull, we want the same again only in a different/opposite direction (left/right). So, what causes this desired change of direction? The answer is vortices, my favourite subject. A waggling lipped lure generates a rapid series of vortices that cause the lure to waggle left and right. The sharp lip causes vortices to be created at a relatively low speed, and the theory of the ‘Kármán vortex street’ causes the vortices to rapidly alternate left/right. But still, the lipped lure requires a minimum speed to operate. The lipless glider still creates vortices but has a much higher minimum speed to create the vortex. The operation of the lure is to tug or jerk the lure. A single vortex is created and no more as the lure is already slowed below the vortex threshold. This swirling vortex sucks on the rear half of the lure body causing it to change direction. The next jerk causes the vortex to form across the back of the lure and sucks it in the opposite direction. As the lure slows down, that single vortex is still there, working on the lure, sucking it further around. This effect can be seen on multiple section swim-baits; a steady, constant retrieve causes alternating vortices that act on the rear of the lure causing that beautiful snake action. BUT, if you jerk the jointed swim-bait, the lure curls around even 90° and beyond. Check out the video, you can almost see the vortex sucking the lure around in the jerk sections with a little imagination. The above is the basic mechanics of what is going on. Now we have to figure out how to use the mechanics, the theory, to make the glider lure swim how we want. To start with, I use an analogy that I have talked about many times; Grab a 2 feet length of dowel in the middle in your fist. Rotate your wrist rapidly left and right. The dowel swings fairly easily. Now add ¼ pound of lead at each end of the dowel and repeat. The dowel is much more difficult to swing left and right. Now put the two weights at the center of the dowel and repeat. Once again, the dowel swings easily. This is the effect of inertia. We want the glider to change direction but we want to resist the continuing change of direction. The solution is to increase resistance to direction change by increasing inertia. By placing weight at the front and rear we increase inertia and resist the change of direction. But as always, design is a compromise. If the inertia of the lure is too great then the change of direction will be minimal or even nonexistent. You may end up with a straight swimming torpedo. Another feature is the depth of the lure body that the suction of the vortex acts upon. You may think that a deeper body with a larger surface area would resist the side movement, this would be incorrect at least according to theory; the suction force of the vortex acts on the side surface area of the lure, reduce the area and reduce the force. But yet again, design is a compromise. If you reduce your lure to a torpedo cylinder, no vortex will be created in the first place. If your lure swings excessively as it slows down then consider reducing the body depth. The reduced depth will also reduce resistance to forward motion. Once the glide motion clears the vortex, it will travel aerodynamically like a torpedo. We only require the vortex sucking effect at the initial tug of the lure, if the glider can swim clear of the vortex then it will continue in a straight line for more distance. If the glide distance is short and the lure continues to turn; reduce body depth and/or extend the weights to front and rear. If the lure does not change direction then no vortex has been created, you have a torpedo. You can add a flat to the top of the nose to help the vortex form, or increase the depth on the next build. Gliders need to naturally float horizontal, but the rest is a compromise between body depth and ballast distribution. Dave1 point

-

Anglin, Thank you for taking the time to explain this. Fantastic post right there. I learned a lot. I'll use all of this as I move forward with my lure making. Thanks again! Most of the trout I fish for are 'stocked"....and I would think might not be anywhere as aggressive as a wild trout. This might be why the fish I catch are only tail hooked. Like you said, they are simply nibbling at the tail of the lure.1 point

-

before you do anything with them get some vinagar and clean the heads in it, rinse and dry really well then heat and try to powder coat them. A friend who used drop out spray had that problem and did the cleaning in vinegar and it took care of the problem1 point

-

Tough question for sure, and a lot of personal opinion is involved. Personally I think it depends on the size of lure, the type of fish you are after, even the type of lure you are making. I should take more time to explain myself on this, but this is the short version. (This could take a chapter of a book to explain) On species that are less aggressive, like many freshwater trout species, I find that the tail hook is important. On larger lures, lures that often work much better than people think, the trout will tail tug or test the lure first and tail hooks really up-the-catch rate. Still, when the fish are aggressive, the trout will hit the front and on larger lures a tail-only hook will miss the strike. On species that are more aggressive, the real predator species, or any species that is fired up, they are eating and an eating fish eats head first so that they can swallow the fish (presumed thing we are imitating) without the fins chocking (getting stuck in the throat) the predator. Even species that "stun" their prey first usually strike head first or center body, so hooks placed more toward the head seem to be the ones that hook up. On lures that invoke reaction strikes, the front to center hooks usually are the ones that hook up IMHO. On lures that are strait swimmers, ones normally used for neutral mood fish (based on active, neutral, or negative moods of feeding fish) the tail hooks are often the ones that take the most fish. On negative mood fish, fish you may need to put the bait on their nose and keep it there for a time, the strike may be at any point and hook placement is always a guess. I could go on and on, and the lines get blurred a lot: for every rule there is an exception, so I don't want to even start trying to say one is better than another, but.......... here is my best advise. On smaller lures relative to fish size (how small is small?), when fishing for aggressive fish, front hooks are probably all you need. On larger lures, relative to fish size, fished for feeding fish, front of center hooks are probably more important, but tail hooks help. On any lure fished for neutral or negative fish, especially larger lures, front of center hooks and tail hooks are important. And..... well you get the point. In my experiences, I have fished a lot of very clear water. In my area, trout, like Rainbow, Cutthroat, and Browns are a common target. I have watched them follow a lure for several feet and just keep picking at the tail. Without a tail hook catching them would be impossible. On the other hand, I have also seen the same fish just appear out of the dark and grab the lure by the front and than a hook front of center is critical. As for a single hook, when used for a tail hook it works fine for me. I often replace my tail hooks with a single hook to make releasing a fish easier. When used for a front of center hook the hook often lays along side the lure and does not connect with the fish. I have used trout as an example because I have so much experience with them, but I have seen similar behavior in species in the Gulf of Mexico, off the coast in the Pacific Northwest of the USA, Musky and Pike in Minnesota, and on and on. I think it was In-Fisherman Magazine that I first saw the explanation of aggressive, neutral and negative feeding moods of fish, but consider this concept when designing your lures. It might help some to answer your questions.1 point

-

Well, I am not a regular fisher, so I will bow to general opinion. But, I do have a lot of success with the belly hook on my tests. Dave1 point

-

I mainly build small lures 2.5" or less. I use the belly hook and delete the tail hook as unnecessary. The belly hook should be far enough back so that it does not foul the lip or the line. The hook dangles roughly in line with the rear of the body. Nothing wrong with a single hook, just more chance of a miss. Dave1 point

-

CNC is a BIG step, so good luck with that one. The problem is that the mould plastic softens with the heat. With the standard 4-corner clamping, the mold will still bow in the center, even clamp plates may not solve this. Clamping needs to be close to the cavities and well distributed. Here is a pic of the mold I was about to have printed, but I have since changed the design in my head, and so needs remodeling. You can see all the clamp bolt holes. As a side note, you can also see that this plate is the same for both halves; flip and rotate 180 degrees. Dave1 point

-

Hi Antonio, Beautiful work! I'm very new to lure building and I have a question. With lures this small, is a belly hook really necessary? In fact, on any size lure how important is the belly hook? Thanks1 point

-

Will let you know mate. Would have to work out a way to do it in such a way that all the different moulds I have made up. Or just size the smaller ones to an arbitrary dimension. But i can see where you are coming from.... Hopefully in the new year ill have a CNC and i can just do it all in aluminium.1 point

-

Try building more clamping holes into the mould, back drill through some plywood backing plates and clamp up the sandwich tight. This is obviously not a convenient solution involving more work in putting the mould halves together, but it may get you more pours or even solve the problem. If you try it then give me feedback, positive or negative. Dave1 point

-

1 point

-

I get my bags from china. Placing my 3rd order this week. I buy 5000 packets at a time Contact Vivian Fong Vivian Fong TOP PACK CO., LIMITED HUIZHOU DINGLI PACKAGING PRODUCTS CO.,LTD E: sales01@toppackhk.com Skype:toppack03 WhatsApp:+86 13414589185 Trademanager:hk1000656717 Moblie :+86 13414589185 / Tele:86-752-3748855 / Fax:86-752-3748885 Add:Floor 2nd, Block 5, JunYuan Industrial Park, BaiShi, QiuChang Street, HuiYang District, HuiZhou City, 516221, China http://toppackhk.en.alibaba.com https://toppackcn.en.alibaba.com http://standuppouchpackaging.com1 point

-

I have two new lure building spreadsheet tools available: 1 - TU resin lure calc – Designed to help with the amount of filler (MBs) and ballast required to achieve the required buoyancy without having to resort to many trial and error builds. 2 - TU wood lure calc – As above but designed for carved lures (wood, PVC or other). Many members have the Ballast Calculator, an older tool. I feel that No2 above is a better tool for this job as it takes into account internal and external hardware as well as ballast. So if anyone requests the Ballast Calculator in future, I will deliver No2 above. If anyone wants these tools, PM me with your email address and I will send both. Dave1 point

-

1 point

-

1 point

-

I believe when I built mine I used the AC Face Mount Gear motor https://www.mcmaster.com/ac-motors/face-mount-compact-ac-gearmotors/ Believe it is the 20 rpm, 25 torque model and jsut use a shaft coupler to connect motor to stir rod. https://www.mcmaster.com/shaft-couplers/set-screw-shaft-couplings/1 point

-

So lowering the temps to 320 made a difference and I also slowed how fast I push down on the injectors. I also verified that the plungers were aligned. All these suggestions helped. thanks1 point

-

Lure Craft watermelon was my favorite when I poured, but I do believe they've changed a few of their formulas.1 point

-

Unfortunately, the PLA melting point is roughly the same temperature that you are pouring, and so severe distortion is unavoidable. You need to find a printing material with a higher temperature tolerance. Distortion can be mitigated by load spreading plates and plenty of clamping. But you still have the problem of pouring into an insulating material with poor cooling qualities. I don't own a printer but class myself as a CAD expert seeing as CAD design has been my job for 35 years. Also, I am hard-baits and so not hampered by the extreme temperatures of the soft-bait pourer. The best that you can do IMO, is print a master and then cast it in POP or some other casting material that can take the heat. As far as hard-baits is concerned, my plan was to print a PLA negative mold to cast a positive mold in another material, designing the PLA negative such that the resulting positive was symmetrical, in other words, both mold halves were identical, so only one PLA master was needed. Unfortunately, the heat distortion from the exothermic reaction of POP or other cast materials made mating the halves impossible. With my financials being stretched and 3D prints costing $100 a time, I cannot throw money at a whim. However, I have a lure design on the go that needs building, and the replication accuracy required means that only 3D printing can give me what I want. I will have to design a positive and print both halves for pouring polyester resin. The design will have a ridiculous number of clamping holes and load spreading wooden plates. The design will help me to determine the minimum clamping required as I try various clamp configurations. I am trying to summon up the enthusiasm to hit the design again as lure wall thickness was a problem on my last attempt, giving incomplete pours. I really do need my own printer as this project is costing me way too much in 3rd party services. I know it makes fiscal sense, but I want to see some success before I commit. The beauty is that if the design is successful, I could take it straight to production injection molding on a grand scale with confidence. Good luck with your project. Dave1 point

-

Let us know if you get this ironed out. After looking at the mold closely, there may be something else if these suggestions don’t straighten out your issue.1 point

-

Been doing it for a few months. I have a basic FDM printer, the ANET A2. I can print moulds and have them inject well with PLA at 0.1mm and 40% fill, but the moulds will warp from the heat over time. Its great for testing ideas, but you do end up with lines from the layers in the final bait. I know some guys who use resin printers, which can print even finer again and they say they get no lines on their baits, but i havent seen the baits close up to be sure.1 point

-

1 point

-

1 point

-

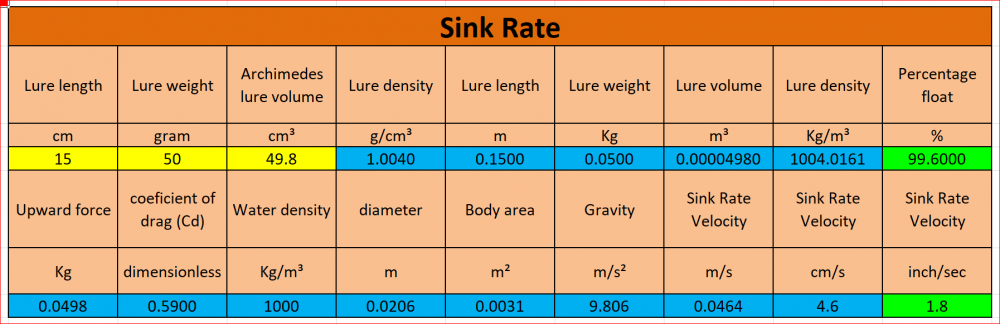

OK, I think that I have cracked the sink rate calculation. Because the plan view shape and cross sectional shape cannot be tabulated, I have used the lure volume and the lure length to calculate the dimensions of a cylindrical body and applied the sink rate formula to this compromise body. I have to say that the numbers look very good. All you have to do is enter the lure length, the lure weight and use ‘Archimedes Dunk Test’ to enter the lure volume. The green boxes show the percentage float (less than 100% = sinker) and the sink rate in inches. The tool is another spreadsheet. PM me your email address if you want to have a play. Dave1 point

-

I can get close by test floating a jerkbait in 60 degree water in my shop. My water gets colder than that, but I use is as a starting point. On the water, I can adjust the float/sink by using either monofilament, which floats, or fluorocarbon, which sinks. Close counts. As long as the bait moves very slowly, either up or down, at rest it will work. Having the patience to test in the shop is the key, because I start with a known quantity that I can adjust on the water.1 point

-

Dave, Thanks for the response man! I do understand that changes in water temperature, mineral content, etc. will affect water density and therefore sink rate and other things. What I am thinking with these baits is an idea I got from some big gliders I bought from Westin. Those gliders sink to between 1.5 and 2 meters and then suspend depending on the factors you stated above. I designed the master for these casts to be somewhat thinner and more tapered toward the tail than the Westin gliders with the intention of them having a more erratic action when fished like a jerk bait. I fish lakes and rivers that vary greatly in depth and weed cover and my intention is to make a variety of these jerks to fit whatever situation I may find myself in. For example, when pike move into the more shallow bay areas before the spawn begins I can often find them in shallower, weedy areas where I would like to get a bait to suspend a couple of meters down but not far enough that it is constantly in the weeds. Another example would be when the perch are feeding close to the surface on summer mornings it would be great to have a small jerk that would suspend about .5 meter below the surface. I will use your spreadsheet to attempt to make something close to what I am envisioning and will let you know how it goes. Once again thank you!1 point